E-mail:Machine@chinaventech.com Expert for pre insulated duct CNC cutting machine.

Ventech Automatic Aluminum Air Grille Diffuser welding machine for air diffusers and air grille diffuser welding machine620

Company Advantages

1. The manufacturing process of VENTECH covers a few major steps. It goes through board cutting, bending, welding of electric parts, PCB handling, and assembling. The components of this product can be disassembled with little effort

2. The product can store as much as solar power during the day to provide a safe and reliable back-up power supply to itself. This product is able to run at a fast and stable manner

3. Our have advantages of high quality and low cost for maintenance. The working speed of this product can be easily set in line with requirements

4. has been become a developing trend of market. This product is characterized by its impact resistance

![]()

![]()

![]()

![]()

![]()

![]()

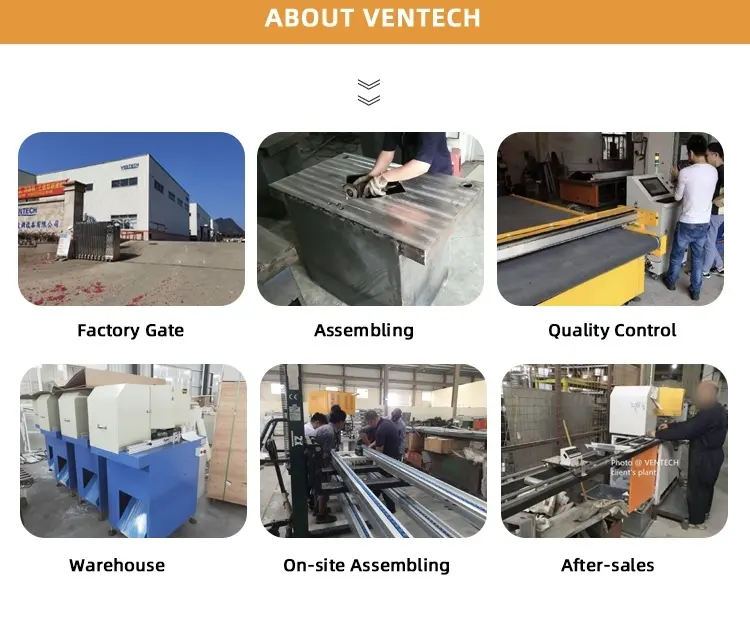

Company Features

1. YINGDE VENTECH INTELLIGENT EQUIPMENT CO., LTD. is good at making , whose product quality is proven by time.

2. Our factory is supported by a series of manufacturing facilities. They incorporate the latest technological advances to constantly help ensure the quality of our products.

3. We will seize any possible opportunity to improve and optimize our service for . Inquire online!

1. The manufacturing process of VENTECH covers a few major steps. It goes through board cutting, bending, welding of electric parts, PCB handling, and assembling. The components of this product can be disassembled with little effort

2. The product can store as much as solar power during the day to provide a safe and reliable back-up power supply to itself. This product is able to run at a fast and stable manner

3. Our have advantages of high quality and low cost for maintenance. The working speed of this product can be easily set in line with requirements

4. has been become a developing trend of market. This product is characterized by its impact resistance

Overview

Quick Details

Showroom Location:None

Video outgoing-inspection:Provided

Machinery Test Report:Provided

Marketing Type:New Product 2020

Warranty of core components:1 Year

Core Components:PLC, Engine, Bearing, Gearbox, Motor, Pressure vessel, Gear, Pump

Brand Name:VENTECH

Condition:NEW

Applicable Industries:Manufacturing Plant, Construction works

Weight:1500 kg

Place of Origin:Guangdong, China

Warranty:1 Year

Key Selling Points:Easy to Operate

Material:Composite material

Usage:for Air Conditioning

Cutting Shapes:Elbow, Shoe, straight cut etc.

Fuction:Cutting phenolic duct parts

Certificate:ISO14001

Material thickness:≤30mm

Cutting Tolerance:0.2mm

Supply Voltag:AC220V, 380V 50Hz

After Warranty Service:Video technical support

After-sales Service Provided:Video technical support

Product Information

Data/ Model | VSCM-2516 | VSCM-1813 |

Working size | 2500*1600mm | 1800*1300mm |

Machine size | 3415*2480*1250mm | 2415*2220*1400mm |

Cutting speed | 80-2,500mm/s | 0-1000mm/s |

Cutting thickness | ≤50mm | ≤40mm |

Cutting accuracy | ≤0.1mm | ≤0.1mm |

Power | 10KW | 7.5KW |

Graphic format supported | AI, Coreldraw, Photoshop, AutoCAD, etc. | AI, Coreldraw, Photoshop, AutoCAD, etc. |

Working voltage | 380V±10%, 50Hz/60Hz | 380V±10%, 50Hz/60Hz |

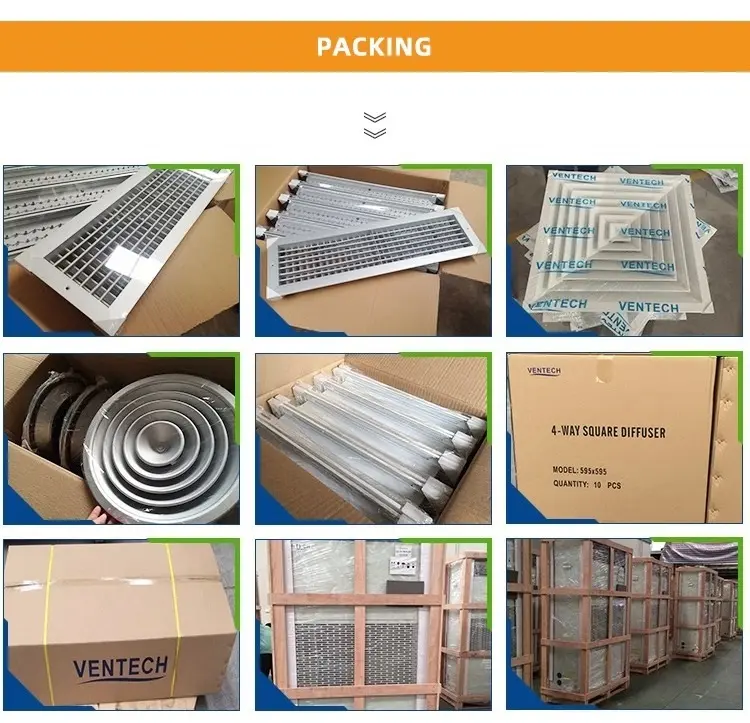

Package | Wooden case | Wooden case |

Product Description

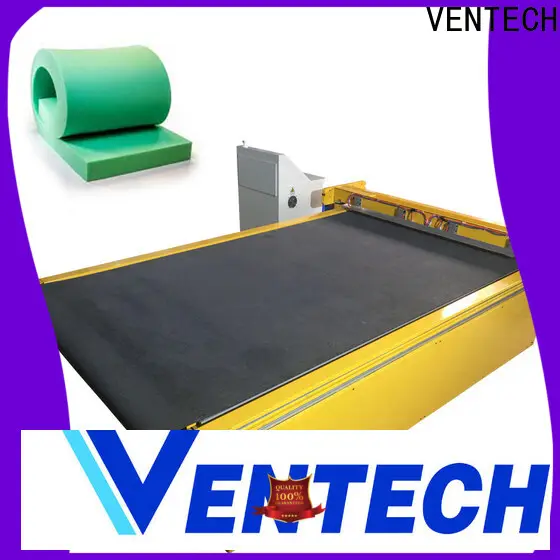

VENTECH insulation cutter can handle insulation, fiberglass etc.

· Optional fixed table (for sheet material) and automatic feeding table (for roll material).

· Vacuum pump for fixing the material.

· No need skilled worker, but operated at high cutting speed, stability and high precision.

· Optional fixed table (for sheet material) and automatic feeding table (for roll material).

· Vacuum pump for fixing the material.

· No need skilled worker, but operated at high cutting speed, stability and high precision.

Product Pictures

With high operational accuracy, the product is not likely to occur errors, which eventually beneficial to reduce production costs. This product is highly resistant to strong chemicals due to its protective coating.

The product has an ever-increasing level of technology and automation to reduce the number of unskilled workers required in the production process. This product is highly resistant to strong chemicals due to its protective coating.

Company Features

1. YINGDE VENTECH INTELLIGENT EQUIPMENT CO., LTD. is good at making , whose product quality is proven by time.

2. Our factory is supported by a series of manufacturing facilities. They incorporate the latest technological advances to constantly help ensure the quality of our products.

3. We will seize any possible opportunity to improve and optimize our service for . Inquire online!

{{item.score}} Stars

{{item.pre}}%

{{item.nickname ? (item.nickname.slice(0, 2) + '*****') : item.source === 1 ? 'mall buyer' : '--'}}

{{item.comment_time}}

Review in the {{item.country}}

{{itemAttr.params_key}}: {{itemAttr.params_value}}

Contact us

we welcome custom designs and ideas and is able to cater to the specific requirements. for more information, please visit the website or contact us directly with questions or inquiries.

you might like

no data

Quick Links

Products

Contact Us

Industrial Zone, Yingde, Qingyuan, Guangdong, China.

Zip Code:513042