E-mail:Machine@chinaventech.com Expert for pre insulated duct CNC cutting machine.

Ventech Automatic Aluminum Air Grille Diffuser welding machine for air diffusers and air grille diffuser welding machine615

Company Advantages

1. The manufacture of VENTECH involves several stages. These include prototype design, cutting and forming metal, soldering, casting, polishing, and final assembling. This product has been widely used for punching and soft material cutting

2. It proves to be great that VENTECH has developed its own sales network. Its operating noise has been reduced as possible

3. This product features fine moisture resistance. Its materials can only absorb moisture to a certain extent. This water absorption influences the technical properties, the printability and the adhesion properties of this product. The product has the ability to generate repeated accuracy

4. The product has good strength. During the production, it is finely welded and die-casted to ensure its physical strength. This product enables operators to work more relaxingly

![]()

![]()

![]()

![]()

![]()

![]()

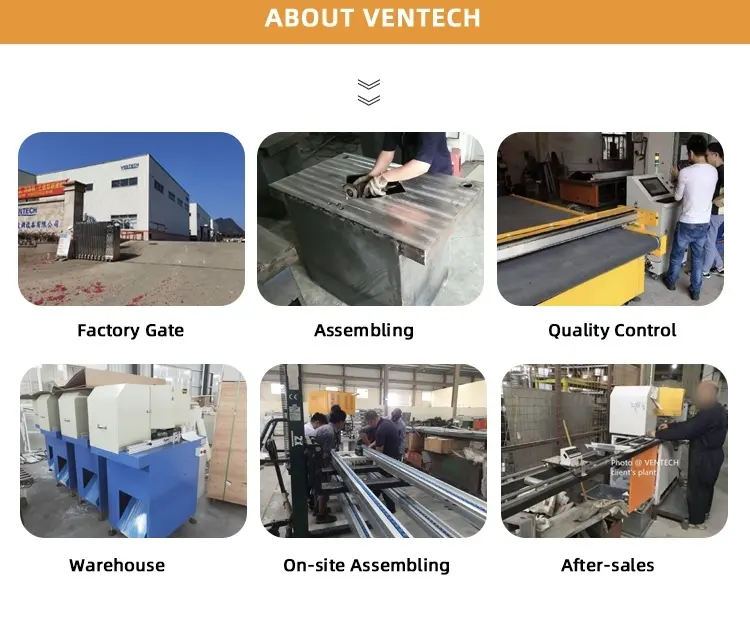

Company Features

1. YINGDE VENTECH INTELLIGENT EQUIPMENT CO., LTD. is a truly qualified manufacturer and provider of that has been meeting the demands of the marketplace since its establishment.

2. We constantly invest in our production facilities and upgrade them each year. The purposes of these facilities are to improve operational efficiency for our orders and raise productivity.

3. Promoting the improvement of for the work is the goal for VENTECH. Please contact us!

1. The manufacture of VENTECH involves several stages. These include prototype design, cutting and forming metal, soldering, casting, polishing, and final assembling. This product has been widely used for punching and soft material cutting

2. It proves to be great that VENTECH has developed its own sales network. Its operating noise has been reduced as possible

3. This product features fine moisture resistance. Its materials can only absorb moisture to a certain extent. This water absorption influences the technical properties, the printability and the adhesion properties of this product. The product has the ability to generate repeated accuracy

4. The product has good strength. During the production, it is finely welded and die-casted to ensure its physical strength. This product enables operators to work more relaxingly

Overview

Quick Details

Showroom Location:None

Video outgoing-inspection:Provided

Machinery Test Report:Provided

Marketing Type:New Product 2020

Warranty of core components:1 Year

Core Components:PLC, Engine, Bearing, Gearbox, Motor, Pressure vessel, Gear, Pump

Brand Name:VENTECH

Condition:NEW

Applicable Industries:Manufacturing Plant, Construction works

Weight:1500 kg

Place of Origin:Guangdong, China

Warranty:1 Year

Key Selling Points:Easy to Operate

Material:Composite material

Usage:for Air Conditioning

Cutting Shapes:Elbow, Shoe, straight cut etc.

Fuction:Cutting phenolic duct parts

Certificate:ISO14001

Material thickness:≤30mm

Cutting Tolerance:0.2mm

Supply Voltag:AC220V, 380V 50Hz

After Warranty Service:Video technical support

After-sales Service Provided:Video technical support

Product Information

Data/ Model | VSCM-2516 | VSCM-1813 |

Working size | 2500*1600mm | 1800*1300mm |

Machine size | 3415*2480*1250mm | 2415*2220*1400mm |

Cutting speed | 80-2,500mm/s | 0-1000mm/s |

Cutting thickness | ≤50mm | ≤40mm |

Cutting accuracy | ≤0.1mm | ≤0.1mm |

Power | 10KW | 7.5KW |

Graphic format supported | AI, Coreldraw, Photoshop, AutoCAD, etc. | AI, Coreldraw, Photoshop, AutoCAD, etc. |

Working voltage | 380V±10%, 50Hz/60Hz | 380V±10%, 50Hz/60Hz |

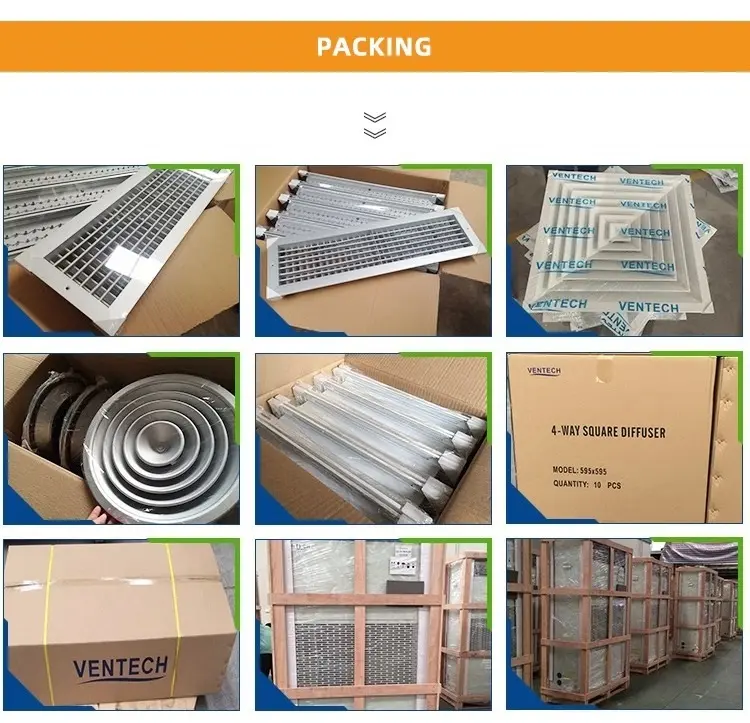

Package | Wooden case | Wooden case |

Product Description

VENTECH insulation cutter can handle insulation, fiberglass etc.

· Optional fixed table (for sheet material) and automatic feeding table (for roll material).

· Vacuum pump for fixing the material.

· No need skilled worker, but operated at high cutting speed, stability and high precision.

· Optional fixed table (for sheet material) and automatic feeding table (for roll material).

· Vacuum pump for fixing the material.

· No need skilled worker, but operated at high cutting speed, stability and high precision.

Product Pictures

With the benefit of increasing production efficiency and output, the product is widely applied in the production of many industries.

This product serves as a useful tool to increase productivity and efficiency. The use of this product can cut down operation times and workload.

Company Features

1. YINGDE VENTECH INTELLIGENT EQUIPMENT CO., LTD. is a truly qualified manufacturer and provider of that has been meeting the demands of the marketplace since its establishment.

2. We constantly invest in our production facilities and upgrade them each year. The purposes of these facilities are to improve operational efficiency for our orders and raise productivity.

3. Promoting the improvement of for the work is the goal for VENTECH. Please contact us!

{{item.score}} Stars

{{item.pre}}%

{{item.nickname ? (item.nickname.slice(0, 2) + '*****') : item.source === 1 ? 'mall buyer' : '--'}}

{{item.comment_time}}

Review in the {{item.country}}

{{itemAttr.params_key}}: {{itemAttr.params_value}}

Contact us

we welcome custom designs and ideas and is able to cater to the specific requirements. for more information, please visit the website or contact us directly with questions or inquiries.

you might like

no data

Quick Links

Products

Contact Us

Industrial Zone, Yingde, Qingyuan, Guangdong, China.

Zip Code:513042