E-mail:Machine@chinaventech.com Expert for pre insulated duct CNC cutting machine.

Ventech Automatic Aluminum Air Grille Diffuser welding machine for air diffusers and air grille diffuser welding machine605

Company Advantages

1. The tests for VENTECH have been conducted. These tests include wiring of main control cabinets, including PLC wiring and operator stations. Its high-speed motor guarantees its high productivity

2. I love them so much! I've dropped these a few times and it is not broken or bent. - Said one of our customers. This product has been widely used for punching and soft material cutting

3. The product features low power or energy consumption. The product, with a compact design, adopts the most advanced energy-saving technology. This product has been certified under CE for safe operation

![]()

![]()

![]()

![]()

![]()

![]()

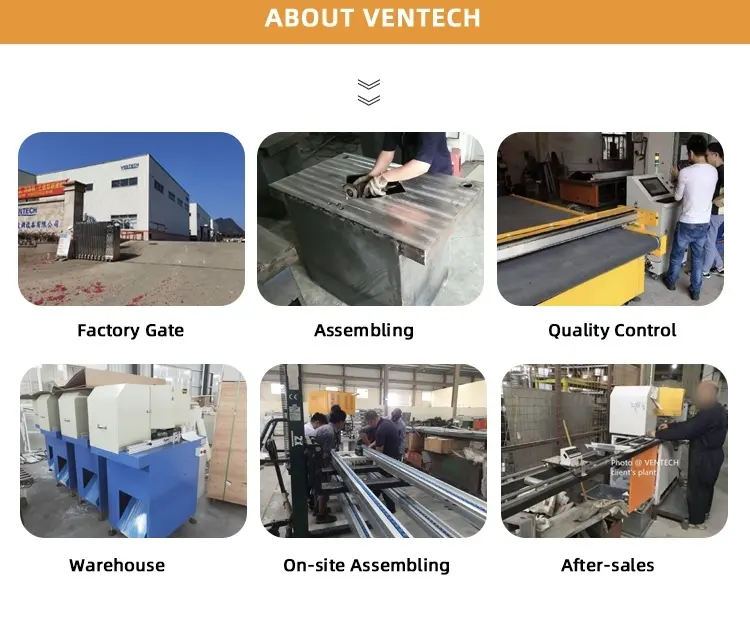

Company Features

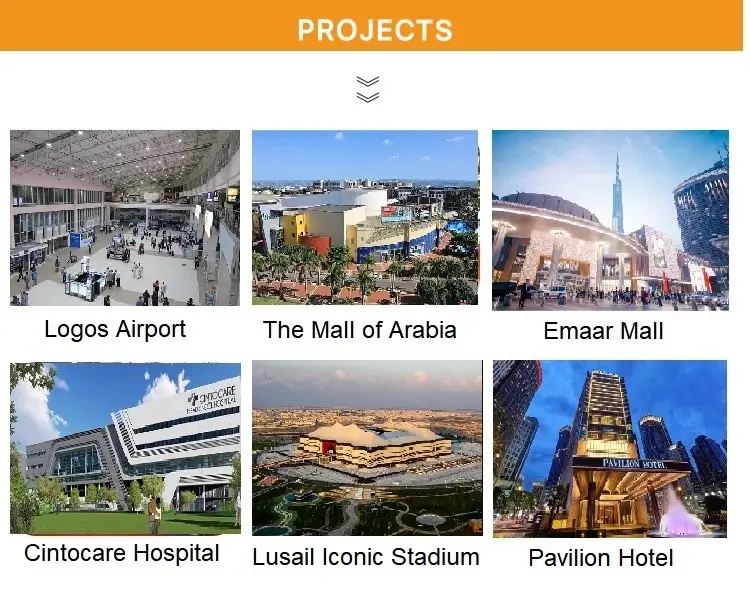

1. YINGDE VENTECH INTELLIGENT EQUIPMENT CO., LTD. has been committed to producing high-quality . Our company is widely accepted by clients all over the world. Our main export markets include Britain, America, France, Spain, Turkey, Canada, Australia, and the Middle East.

2. We have a positive workforce. The members have a good command of industry changes and the latest technology changes. They allow the company to move forward and remain competitive.

3. Our professional R&D team has accumulated abundant technical know-how. This advantage enables them to create satisfactory products that will meet market requirements and provide professional advice. VENTECH will continue to give full play to the important role of culture in improving corporate management. Check it!

1. The tests for VENTECH have been conducted. These tests include wiring of main control cabinets, including PLC wiring and operator stations. Its high-speed motor guarantees its high productivity

2. I love them so much! I've dropped these a few times and it is not broken or bent. - Said one of our customers. This product has been widely used for punching and soft material cutting

3. The product features low power or energy consumption. The product, with a compact design, adopts the most advanced energy-saving technology. This product has been certified under CE for safe operation

Overview

Quick Details

Showroom Location:None

Video outgoing-inspection:Provided

Machinery Test Report:Provided

Marketing Type:New Product 2020

Warranty of core components:1 Year

Core Components:PLC, Engine, Bearing, Gearbox, Motor, Pressure vessel, Gear, Pump

Brand Name:VENTECH

Condition:NEW

Applicable Industries:Manufacturing Plant, Construction works

Weight:5000 kg

Place of Origin:Guangdong, China

Warranty:1 Year

Key Selling Points:Easy to Operate

Material:Composite material

Usage:for Air Conditioning

Cutting Shapes:Elbow, Shoe, straight cut etc.

Fuction:Cutting phenolic duct parts

Certificate:ISO14001

Material thickness:≤30mm

Cutting Tolerance:0.2mm

Supply Voltag:AC220V, 380V 50Hz

After Warranty Service:Video technical support

Product Information

Working size | 2500x1600mm |

Material fixing way | Vacuum suction system |

Cutting speed | 80-2,500mm/s(according to different material) |

Cutting thickness | ≤50mm |

Cutting accuracy | ≤0.1mm |

Drive system | servo driver |

Transmission system | linear square rail & belt |

Instruction system | HP-GL compatible format |

Vacuum pump power | 10.7KW |

Graphic format supported | PLT, DXF, AI, HPJ, etc. |

Compatible | CORELDRAW, PHOTOSHOP, AUTOCAD, etc. |

Safety device | Infrared sensors & emergency stop devices |

Working voltage | 380V±10%, 50Hz/60Hz |

Package | Wooden case |

Machine size | 3415×2480×1250mm |

Product Description

VENTECH insulation cutting machine is suitable for fiberglass and external thermal insulation cutting for HVAC ductwork. With our simple and smooth operating system, the complex graphics and product can be easily, precisely, and rapidly cut and produced, for material HVAC duct insulation with aluminum foil or with foil, or temperature insulation, this fiberglass cutter or duct insulation cutting machine permits to obtain finished pieces for ducts in pre-insulated; no more hand operations to do, the pieces obtained are ready to be glued. The standard machine is completed with a large quantity of accessories and devices dedicated to reduce the production time and generate the best quality of finished product.

Product Pictures

The product enables manufacturers free from the risk of staff shortages. It significantly helps reduce the number of needed workers for production. It can be customized into a horizontal or vertical style.

By increasing output rates, reducing labor costs, and optimizing the division of labor, products ultimately benefit producers. It can be customized into a horizontal or vertical style.

Company Features

1. YINGDE VENTECH INTELLIGENT EQUIPMENT CO., LTD. has been committed to producing high-quality . Our company is widely accepted by clients all over the world. Our main export markets include Britain, America, France, Spain, Turkey, Canada, Australia, and the Middle East.

2. We have a positive workforce. The members have a good command of industry changes and the latest technology changes. They allow the company to move forward and remain competitive.

3. Our professional R&D team has accumulated abundant technical know-how. This advantage enables them to create satisfactory products that will meet market requirements and provide professional advice. VENTECH will continue to give full play to the important role of culture in improving corporate management. Check it!

{{item.score}} Stars

{{item.pre}}%

{{item.nickname ? (item.nickname.slice(0, 2) + '*****') : item.source === 1 ? 'mall buyer' : '--'}}

{{item.comment_time}}

Review in the {{item.country}}

{{itemAttr.params_key}}: {{itemAttr.params_value}}

Contact us

we welcome custom designs and ideas and is able to cater to the specific requirements. for more information, please visit the website or contact us directly with questions or inquiries.

you might like

no data

Quick Links

Products

Contact Us

Industrial Zone, Yingde, Qingyuan, Guangdong, China.

Zip Code:513042