E-mail:Machine@chinaventech.com Expert for pre insulated duct CNC cutting machine.

Ventech Automatic Aluminum Air Grille Diffuser welding machine for air diffusers and air grille diffuser welding machine56

Company Advantages

1. VENTECH is carefully crafted by our skillful workers who utilize advanced production equipment. This product is less likely to generate vibration during operation

2. is delivered with good outer package. This product has been certified under CE for safe operation

3. This product is corrosion resistant. It has been tested in salt fog harsh environment to determine its resistance to the effects of a salt atmosphere. The product has the ability to generate repeated accuracy

4. This product has a precise dimension. Its manufacturing process adopts the CNC machines and advanced technologies, which guarantee its accuracy in size and shape. It can be painted with a variety of colors for the sake of recognition

5. The product can work with high accuracy. Its distinguished self-diagnostic feature can make sure that every motion is of high accuracy. Its operating noise has been reduced as possible

![]()

![]()

![]()

![]()

![]()

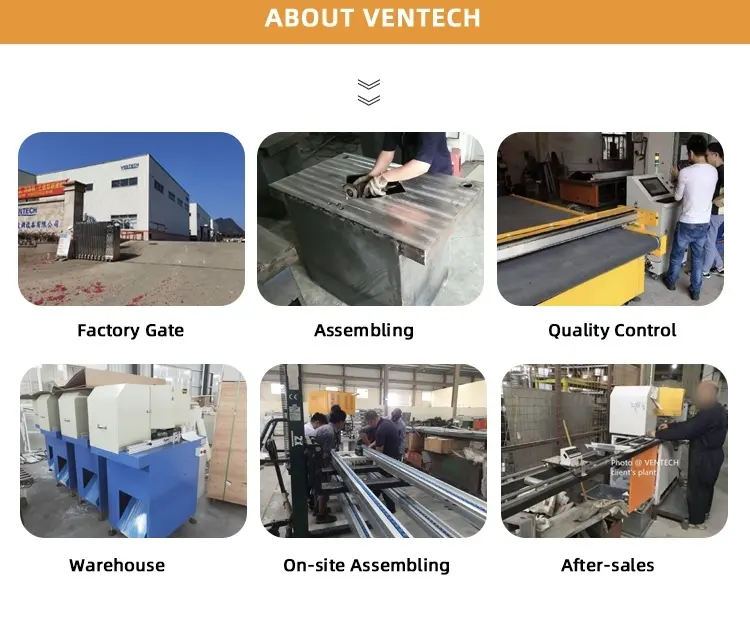

Company Features

1. We have brought together an in-house QC team. They are in charge of the quality of the product by using various kinds of testing devices, enabling us to provide high-quality products for our customers.

2. As a fast-growing company, we work to develop and maintain sustainable relationships with all stakeholders. We demonstrate this commitment by acting imaginatively and consistently in the communities where our employees, business partners, and customers live and work.

1. VENTECH is carefully crafted by our skillful workers who utilize advanced production equipment. This product is less likely to generate vibration during operation

2. is delivered with good outer package. This product has been certified under CE for safe operation

3. This product is corrosion resistant. It has been tested in salt fog harsh environment to determine its resistance to the effects of a salt atmosphere. The product has the ability to generate repeated accuracy

4. This product has a precise dimension. Its manufacturing process adopts the CNC machines and advanced technologies, which guarantee its accuracy in size and shape. It can be painted with a variety of colors for the sake of recognition

5. The product can work with high accuracy. Its distinguished self-diagnostic feature can make sure that every motion is of high accuracy. Its operating noise has been reduced as possible

Overview

Quick Details

Showroom Location:None

Video outgoing-inspection:Provided

Machinery Test Report:Provided

Marketing Type:New Product 2020

Warranty of core components:1 Year

Core Components:PLC, Engine, Bearing, Gearbox, Motor, Pressure vessel, Gear, Pump

Brand Name:VENTECH

Condition:NEW

Applicable Industries:Manufacturing Plant, Construction works

Weight:400 kg

Place of Origin:Guangdong, China

Warranty:1 Year

Key Selling Points:Easy to Operate

Material:Composite material

Usage:for Air Conditioning

Cutting Shapes:Elbow, Shoe, straight cut etc.

Fuction:Cutting phenolic duct parts

Certificate:ISO14001

Material thickness:≤30mm

Cutting Tolerance:0.2mm

Supply Voltag:AC220V, 380V 50Hz

After Warranty Service:Video technical support

Product Information

Model | VCM-300 |

Cutting angle | 45 degree |

Cutting width | <90mm |

Cutting length | no limitation |

Power supply | 380v/50hz |

Cutting speed | 15pcs/min |

Designed production capacity | 7200pcs/day(8hours) |

Machine size | 1500*850*1450mm |

N.W./G.W. | 260/350kg |

Package | Wooden case |

Product Description

(1)VCM-300 is a double saw blades cutting machine.

(2)It's designed to cut aluminum profiles into 45° angles.

(3)It's usually used for cutting aluminum grilles profiles, window profiles, door profiles.

(4)It improves production capacity, saving time and labor cost.

(5)Easy cleaning of the cutting scratches.

(2)It's designed to cut aluminum profiles into 45° angles.

(3)It's usually used for cutting aluminum grilles profiles, window profiles, door profiles.

(4)It improves production capacity, saving time and labor cost.

(5)Easy cleaning of the cutting scratches.

Product Pictures

This product greatly increases productivity. It greatly helps manufacturers reduce the cost and time required to complete engineering projects. With an intuitive touch screen, it allows users to easily take control of the entire production process.

Operators are fond of using this product mainly due to the simple and easy operation. Without complicated procedure, it brings convenience and increases efficiency. With an intuitive touch screen, it allows users to easily take control of the entire production process.

Company Features

1. We have brought together an in-house QC team. They are in charge of the quality of the product by using various kinds of testing devices, enabling us to provide high-quality products for our customers.

2. As a fast-growing company, we work to develop and maintain sustainable relationships with all stakeholders. We demonstrate this commitment by acting imaginatively and consistently in the communities where our employees, business partners, and customers live and work.

{{item.score}} Stars

{{item.pre}}%

{{item.nickname ? (item.nickname.slice(0, 2) + '*****') : item.source === 1 ? 'mall buyer' : '--'}}

{{item.comment_time}}

Review in the {{item.country}}

{{itemAttr.params_key}}: {{itemAttr.params_value}}

Contact us

we welcome custom designs and ideas and is able to cater to the specific requirements. for more information, please visit the website or contact us directly with questions or inquiries.

you might like

no data

Quick Links

Products

Contact Us

Industrial Zone, Yingde, Qingyuan, Guangdong, China.

Zip Code:513042