E-mail:Machine@chinaventech.com Expert for pre insulated duct CNC cutting machine.

Ventech Automatic Aluminum Air Grille Diffuser welding machine for air diffusers and air grille diffuser welding machine434

Company Advantages

1. The development of VENTECH incorporates various advantages. It is developed with a wider input voltage range, high electromagnetic compatibility, good insulation performance, and surge endurance capacity. The dust will be not easy to accumulate on this product

2. With the help of this product, large scale production is possible with less investment in less time. It could be a valuable asset for the company. This product stands out for its outstanding lubricating effect

3. Its electric circuits react flexibly and actively to the transmitted signals, which directly helps reduce the signal distortion rate. This product has been praised by its prominent energy-saving effect

4. The product is characterized by excellent resilience. It has the ability to return to its original size and shape following a temporary deformation, such as contact with a metal surface. This product has been widely used for punching and soft material cutting

5. The product features excellent shock resistance. Its lamp shade is made of aluminum alloy, which allows it to withstand any collision. Its modular design makes the replacement for parts easier

![]()

![]()

![]()

![]()

![]()

![]()

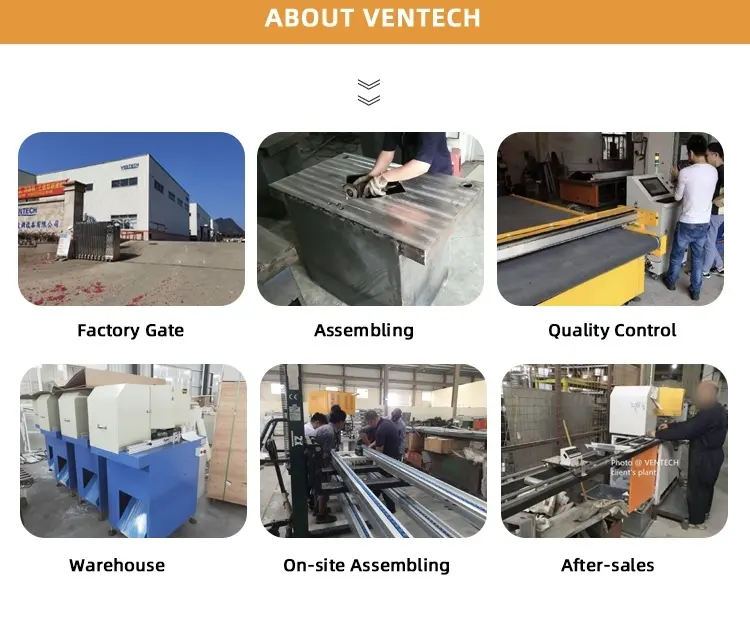

Company Features

1. Our company features a dedicated management team. They have gained a wealth of industry know-how and management skills, which is a guarantee of our high-efficient manufacturing process.

2. We will make all of our business activities meet the legal statutes of environmental protection. We promise not to carry out any practices that will harm society and our environment.

1. The development of VENTECH incorporates various advantages. It is developed with a wider input voltage range, high electromagnetic compatibility, good insulation performance, and surge endurance capacity. The dust will be not easy to accumulate on this product

2. With the help of this product, large scale production is possible with less investment in less time. It could be a valuable asset for the company. This product stands out for its outstanding lubricating effect

3. Its electric circuits react flexibly and actively to the transmitted signals, which directly helps reduce the signal distortion rate. This product has been praised by its prominent energy-saving effect

4. The product is characterized by excellent resilience. It has the ability to return to its original size and shape following a temporary deformation, such as contact with a metal surface. This product has been widely used for punching and soft material cutting

5. The product features excellent shock resistance. Its lamp shade is made of aluminum alloy, which allows it to withstand any collision. Its modular design makes the replacement for parts easier

Overview

Quick Details

Showroom Location:None

Video outgoing-inspection:Provided

Machinery Test Report:Provided

Marketing Type:New Product 2020

Warranty of core components:1 Year

Core Components:PLC, Engine, Bearing, Gearbox, Motor, Pressure vessel, Gear, Pump

Brand Name:VENTECH

Condition:NEW

Applicable Industries:Manufacturing Plant, Construction works

Weight:5000 kg

Place of Origin:Guangdong, China

Warranty:1 Year

Key Selling Points:Easy to Operate

Material:Composite material

Usage:for Air Conditioning

Cutting Shapes:Elbow, Shoe, straight cut etc.

Fuction:Cutting phenolic duct parts

Certificate:ISO14001

Material thickness:≤30mm

Cutting Tolerance:0.2mm

Supply Voltag:AC220V, 380V 50Hz

After Warranty Service:Video technical support

Product Information

Working size | 2500x1600mm |

Material fixing way | Vacuum suction system |

Cutting speed | 80-2,500mm/s(according to different material) |

Cutting thickness | ≤50mm |

Cutting accuracy | ≤0.1mm |

Drive system | servo driver |

Transmission system | linear square rail & belt |

Instruction system | HP-GL compatible format |

Vacuum pump power | 10.7KW |

Graphic format supported | PLT, DXF, AI, HPJ, etc. |

Compatible | CORELDRAW, PHOTOSHOP, AUTOCAD, etc. |

Safety device | Infrared sensors & emergency stop devices |

Working voltage | 380V±10%, 50Hz/60Hz |

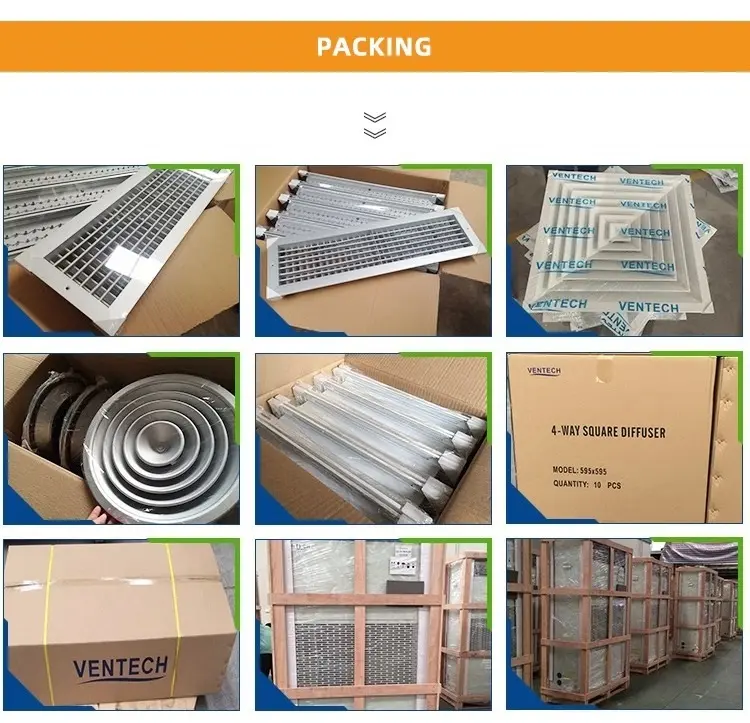

Package | Wooden case |

Machine size | 3415×2480×1250mm |

Product Description

VENTECH insulation cutting machine is suitable for fiberglass and external thermal insulation cutting for HVAC ductwork. With our simple and smooth operating system, the complex graphics and product can be easily, precisely, and rapidly cut and produced, for material HVAC duct insulation with aluminum foil or with foil, or temperature insulation, this fiberglass cutter or duct insulation cutting machine permits to obtain finished pieces for ducts in pre-insulated; no more hand operations to do, the pieces obtained are ready to be glued. The standard machine is completed with a large quantity of accessories and devices dedicated to reduce the production time and generate the best quality of finished product.

Product Pictures

It can be modified flexibly based on the customers' requirements. It can be customized into a horizontal or vertical style.

The employees of VENTECH has been committed to offer the most professional service for customers. It can be customized into a horizontal or vertical style.

Company Features

1. Our company features a dedicated management team. They have gained a wealth of industry know-how and management skills, which is a guarantee of our high-efficient manufacturing process.

2. We will make all of our business activities meet the legal statutes of environmental protection. We promise not to carry out any practices that will harm society and our environment.

{{item.score}} Stars

{{item.pre}}%

{{item.nickname ? (item.nickname.slice(0, 2) + '*****') : item.source === 1 ? 'mall buyer' : '--'}}

{{item.comment_time}}

Review in the {{item.country}}

{{itemAttr.params_key}}: {{itemAttr.params_value}}

Contact us

we welcome custom designs and ideas and is able to cater to the specific requirements. for more information, please visit the website or contact us directly with questions or inquiries.

you might like

no data

Quick Links

Products

Contact Us

Industrial Zone, Yingde, Qingyuan, Guangdong, China.

Zip Code:513042