E-mail:Machine@chinaventech.com Expert for pre insulated duct CNC cutting machine.

Ventech Automatic Aluminum Air Grille Diffuser welding machine for air diffusers and air grille diffuser welding machine317

Company Advantages

1. VENTECH is of green design. It meets standards of energy-efficient building design, building code development, and energy efficiency policy development. With an intuitive touch screen, it allows users to easily take control of the entire production process

2. This product can make the work environment safer as having it means having fewer employees who perform tasks that can be dangerous and prone to injury. This product is characterized by its impact resistance

3. 's design uses concept, is . Its advanced serve system allows it to avoid unnecessary production waste

4. Our is not only beautiful but also durable. The working speed of this product can be easily set in line with requirements

5. has the features of . Measurements show that it is . This product has been greatly upgraded to reduce the chance of production downtime

![]()

![]()

![]()

![]()

![]()

![]()

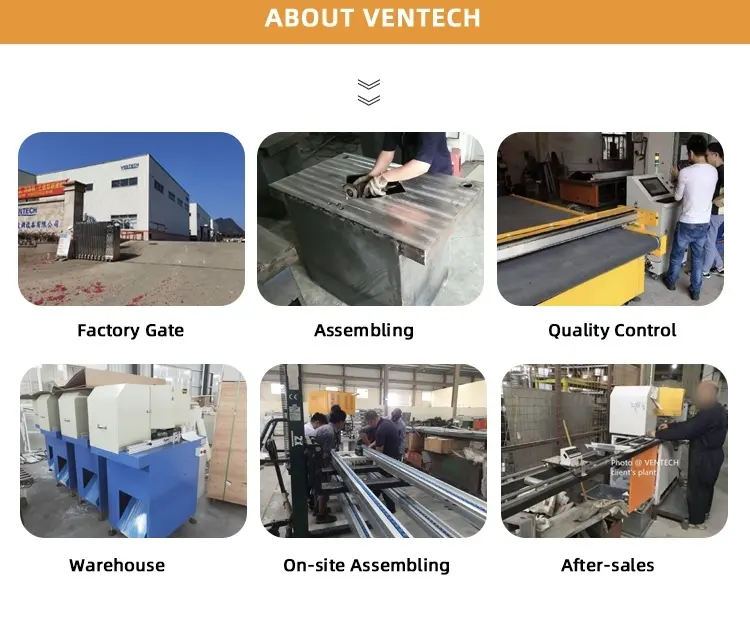

Company Features

1. Having achieved high quality and low cost, development is rapid which is a qualitative leap for VENTECH.

2. Sustainability is part of the ever-renewing commitment we make to our customers. We consider ourselves to have a duty of care towards people outside our company.

1. VENTECH is of green design. It meets standards of energy-efficient building design, building code development, and energy efficiency policy development. With an intuitive touch screen, it allows users to easily take control of the entire production process

2. This product can make the work environment safer as having it means having fewer employees who perform tasks that can be dangerous and prone to injury. This product is characterized by its impact resistance

3. 's design uses concept, is . Its advanced serve system allows it to avoid unnecessary production waste

4. Our is not only beautiful but also durable. The working speed of this product can be easily set in line with requirements

5. has the features of . Measurements show that it is . This product has been greatly upgraded to reduce the chance of production downtime

Overview

Quick Details

Showroom Location:None

Video outgoing-inspection:Provided

Machinery Test Report:Provided

Marketing Type:New Product 2020

Warranty of core components:1 Year

Core Components:PLC, Engine, Bearing, Gearbox, Motor, Pressure vessel, Gear, Pump

Brand Name:VENTECH

Condition:NEW

Applicable Industries:Manufacturing Plant, Construction works

Weight:1500 kg

Place of Origin:Guangdong, China

Warranty:1 Year

Key Selling Points:Easy to Operate

Material:Composite material

Usage:for Air Conditioning

Cutting Shapes:Elbow, Shoe, straight cut etc.

Fuction:Cutting phenolic duct parts

Certificate:ISO14001

Material thickness:≤30mm

Cutting Tolerance:0.2mm

Supply Voltag:AC220V, 380V 50Hz

After Warranty Service:Video technical support

After-sales Service Provided:Video technical support

Product Information

Working size | 2500x1600mm |

Material fixing way | Vacuum suction system |

Cutting speed | 80-2,500mm/s(according to different material) |

Cutting thickness | ≤50mm |

Cutting accuracy | ≤0.1mm |

Drive system | servo driver |

Transmission system | linear square rail & belt |

Instruction system | HP-GL compatible format |

Vacuum pump power | 10.7KW |

Graphic format supported | PLT, DXF, AI, HPJ, etc. |

Compatible | CORELDRAW, PHOTOSHOP, AUTOCAD, etc. |

Safety device | Infrared sensors & emergency stop devices |

Working voltage | 380V±10%, 50Hz/60Hz |

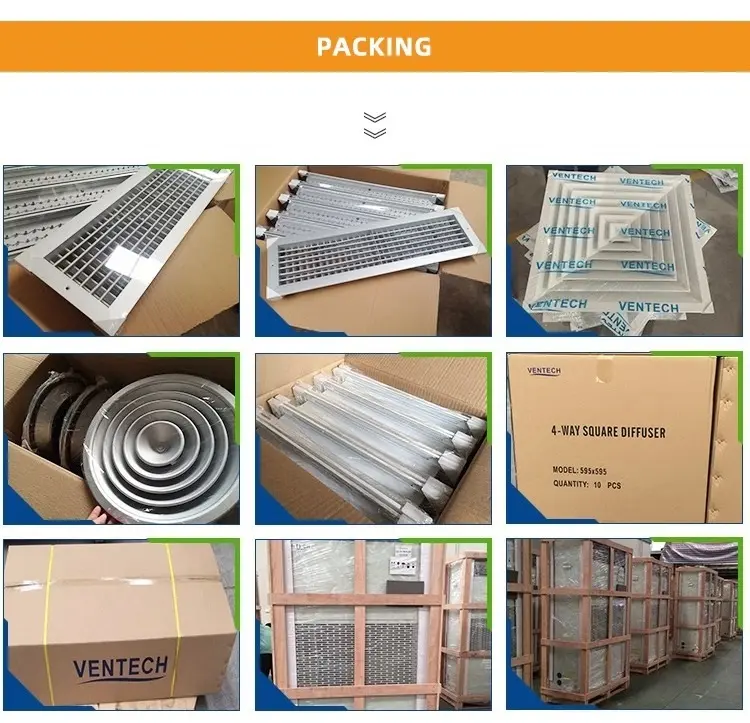

Package | Wooden case |

Machine size | 3415×2480×1250mm |

Product Description

VENTECH insulation cutting machine is suitable for fiberglass and external thermal insulation cutting for HVAC ductwork. With our simple and smooth operating system, the complex graphics and product can be easily, precisely, and rapidly cut and produced, for material HVAC duct insulation with aluminum foil or with foil, or temperature insulation, this fiberglass cutter or duct insulation cutting machine permits to obtain finished pieces for ducts in pre-insulated; no more hand operations to do, the pieces obtained are ready to be glued. The standard machine is completed with a large quantity of accessories and devices dedicated to reduce the production time and generate the best quality of finished product.

Product Pictures

The market share of the product is getting increasingly larger, showing its wide market application. This product has been widely used for punching and soft material cutting.

The product is applicable to various fields and has a huge market prospect. This product has been widely used for punching and soft material cutting.

Company Features

1. Having achieved high quality and low cost, development is rapid which is a qualitative leap for VENTECH.

2. Sustainability is part of the ever-renewing commitment we make to our customers. We consider ourselves to have a duty of care towards people outside our company.

{{item.score}} Stars

{{item.pre}}%

{{item.nickname ? (item.nickname.slice(0, 2) + '*****') : item.source === 1 ? 'mall buyer' : '--'}}

{{item.comment_time}}

Review in the {{item.country}}

{{itemAttr.params_key}}: {{itemAttr.params_value}}

Contact us

we welcome custom designs and ideas and is able to cater to the specific requirements. for more information, please visit the website or contact us directly with questions or inquiries.

you might like

no data

Quick Links

Products

Contact Us

Industrial Zone, Yingde, Qingyuan, Guangdong, China.

Zip Code:513042