E-mail:Machine@chinaventech.com Expert for pre insulated duct CNC cutting machine.

Ventech Automatic Aluminum Air Grille Diffuser welding machine for air diffusers and air grille diffuser welding machine253

Company Advantages

1. Testing for VENTECH includes several aspects. It will be tested in terms of its work blank, components and parts, and raw materials in virtue of measuring appliances that are designed for the machinery. This product is safe enough to operate since it has no sharp edges

2. People will not blame for any wear and tear or other problems with this product they might buy, due to its wear resistance. Its high-speed motor guarantees its high productivity

3. The product excels in performance, durability and usability. Its advanced serve system allows it to avoid unnecessary production waste

4. Internationally-certified quality: The product, tested by the authoritative third-party, has been approved to meet with the widely-recognized international quality standards. The working speed of this product can be easily set in line with requirements

5. This product has good durability and is suitable for long-term use and storage.

![]()

![]()

![]()

![]()

![]()

![]()

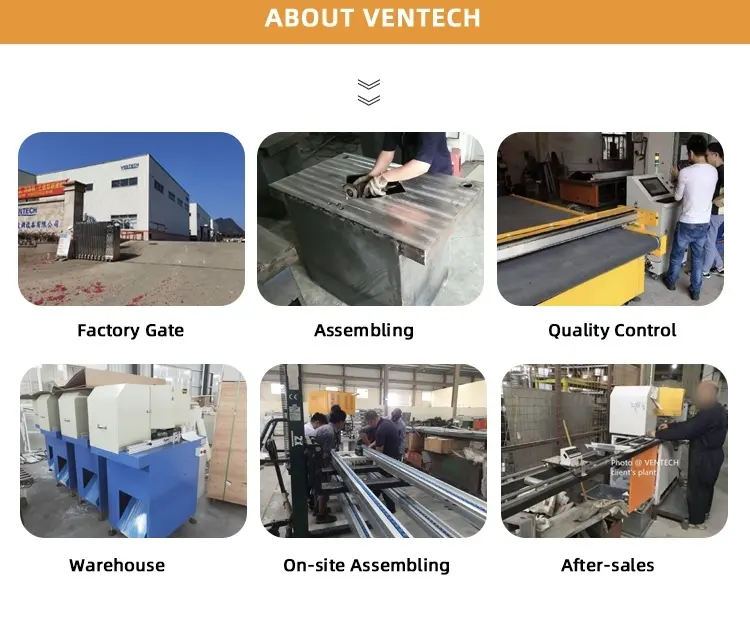

Company Features

1. VENTECH realizes that the bottleneck of manufacturing can be broken by implementing new technologies.

2. Increasing customer demand drives the development of VENTECH.

1. Testing for VENTECH includes several aspects. It will be tested in terms of its work blank, components and parts, and raw materials in virtue of measuring appliances that are designed for the machinery. This product is safe enough to operate since it has no sharp edges

2. People will not blame for any wear and tear or other problems with this product they might buy, due to its wear resistance. Its high-speed motor guarantees its high productivity

3. The product excels in performance, durability and usability. Its advanced serve system allows it to avoid unnecessary production waste

4. Internationally-certified quality: The product, tested by the authoritative third-party, has been approved to meet with the widely-recognized international quality standards. The working speed of this product can be easily set in line with requirements

5. This product has good durability and is suitable for long-term use and storage.

Overview

Quick Details

Showroom Location:None

Video outgoing-inspection:Provided

Machinery Test Report:Provided

Marketing Type:New Product 2020

Warranty of core components:1 Year

Core Components:PLC, Engine, Bearing, Gearbox, Motor, Pressure vessel, Gear, Pump

Brand Name:VENTECH

Condition:NEW

Applicable Industries:Manufacturing Plant, Construction works

Weight:400 kg

Place of Origin:Guangdong, China

Warranty:1 Year

Key Selling Points:Easy to Operate

Material:Composite material

Usage:for Air Conditioning

Cutting Shapes:Elbow, Shoe, straight cut etc.

Fuction:Cutting phenolic duct parts

Certificate:ISO14001

Material thickness:≤30mm

Cutting Tolerance:0.2mm

Supply Voltag:AC220V, 380V 50Hz

After Warranty Service:Video technical support

MOQ:1 Set

Product Information

Model | VCM-300 |

Cutting angle | 45 degree |

Cutting width | <90mm |

Cutting length | no limitation |

Power supply | 380v/50hz |

Cutting speed | 15pcs/min |

Designed production capacity | 7200pcs/day(8hours) |

Machine size | 1500*850*1450mm |

N.W./G.W. | 260/350kg |

Package | Wooden case |

Product Description

(1)VCM-300 is a double saw blades cutting machine.

(2)It's designed to cut aluminum profiles into 45° angles.

(3)It's usually used for cutting aluminum grilles profiles, window profiles, door profiles.

(4)It improves production capacity, saving time and labor cost.

(5)Easy cleaning of the cutting scratches.

(2)It's designed to cut aluminum profiles into 45° angles.

(3)It's usually used for cutting aluminum grilles profiles, window profiles, door profiles.

(4)It improves production capacity, saving time and labor cost.

(5)Easy cleaning of the cutting scratches.

Product Pictures

The internal R&D capability and efficiency of YINGDE VENTECH INTELLIGENT EQUIPMENT CO., LTD. are impressive. Easy to care for, this product helps save maintenance costs for factory owners.

YINGDE VENTECH INTELLIGENT EQUIPMENT CO., LTD. appears to have secured competitive advantage in pre insulated ductwork markets. Easy to care for, this product helps save maintenance costs for factory owners.

Company Features

1. VENTECH realizes that the bottleneck of manufacturing can be broken by implementing new technologies.

2. Increasing customer demand drives the development of VENTECH.

{{item.score}} Stars

{{item.pre}}%

{{item.nickname ? (item.nickname.slice(0, 2) + '*****') : item.source === 1 ? 'mall buyer' : '--'}}

{{item.comment_time}}

Review in the {{item.country}}

{{itemAttr.params_key}}: {{itemAttr.params_value}}

Contact us

we welcome custom designs and ideas and is able to cater to the specific requirements. for more information, please visit the website or contact us directly with questions or inquiries.

you might like

no data

Quick Links

Products

Contact Us

Industrial Zone, Yingde, Qingyuan, Guangdong, China.

Zip Code:513042