E-mail:Machine@chinaventech.com Expert for pre insulated duct CNC cutting machine.

What Are the Most Common Mistakes When Cutting Ducts?

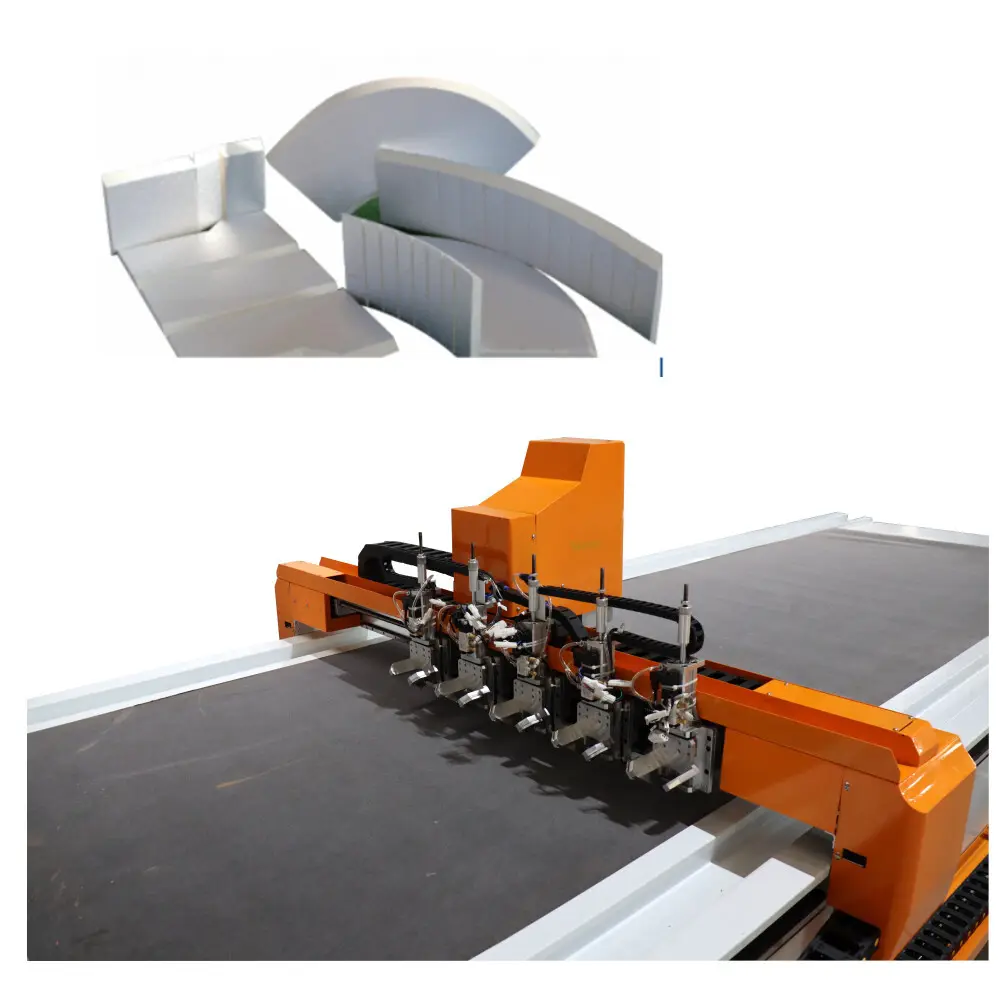

Proper duct cutting techniques are essential for efficient and safe HVAC system performance. Accurate cuts enhance system efficiency by reducing energy waste and ensure precise fitting and proper sealing, which is crucial for maintaining optimal indoor air quality. Using the right tools and techniques, such as pneumatic cutters for speed and precision and plasma cutters for thicker metal ducts, is key. Regular maintenance and the use of multi-purpose tools that can handle various materials are essential for minimizing costs and wear. Duct material type significantly influences the cutting process, with galvanized steel requiring diamond-coated blades to resist dulling and aluminum demanding keenly sharp and well-maintained tools to avoid damage. Precise cuts and efficient techniques, combined with strategic use of guides and templates, are particularly important in tight duct layouts to minimize errors and ensure proper airflow.

Common Mistakes in Cutting Ducts for HVAC Systems

Common mistakes in cutting ducts for HVAC systems often include the incorrect use of cutting tools, leading to jagged edges and weakened sections, which compromise the structural integrity and efficiency of the system. Cutting too close to edges or connections can result in leaks and increased maintenance costs. Providing adequate support around the cuts to prevent stress concentrations and potential failures is crucial. Ensuring a clean and precise cut is essential for long-term performance, as debris and misalignments can affect the system's efficiency and longevity. Using appropriate tools like multipurpose lubricants and blade guides, along with selecting suitable reinforcement materials such as galvanized or stainless steel straps, can significantly improve the system's reliability. Design aspects, including duct material, size, and layout, significantly impact the cutting and reinforcing methods, and proper consideration of these factors can lead to more efficient and less costly installations.

Tips for Accurate Duct Cuts in HVAC Installation

Accurate duct cuts are pivotal for efficient HVAC installations. Precisely measured and aligned ducts ensure optimal air distribution, reducing noise levels and improving air quality, which enhances overall building performance and occupant comfort. Modern tools such as laser-cutting devices and CNC cutters play a critical role in achieving these standards, but careful calibration and integration into the workflow are essential. Double-checking measurements and using advanced templates or guides are crucial for maintaining precision. Engaging with homeowners early in the design phase and providing educational materials ensures their understanding and cooperation. Involving HVAC professionals in the initial design process helps prevent clashes with other elements and ensures seamless integration with the buildings structure.

Best Practices for Duct Cutting in Plumbing Installations

Precision is paramount when cutting ducts in plumbing installations. Careful measurement and selection of appropriate cutting tools, such as laser-guided cutters and precision saws, enhance accuracy and minimize material waste. Ensuring smooth and flush edges is crucial to prevent air leaks and maintain system efficiency. Immediate sealing with high-quality materials, such as mineral fiber tape and mastic, is essential to create a tight and airtight duct system. Using advanced tools and techniques, such as integrated dust extraction systems and protective enclosures, contributes to a safer and more productive work environment. Integrating smart technologies and sensors post-installation provides real-time data on system performance, allowing adjustments that maximize energy efficiency and indoor air quality. Compliance with building codes and industry standards, including those from ASHRAE and IPC, ensures safety and regulatory adherence. Proactive coordination and effective project management using digital tools streamline the process, ensuring timely completion without compromising quality.

Consequences of Improper Duct Cutting on Residential Plumbing Systems

Improper duct cutting can lead to significant and far-reaching consequences for residential plumbing systems. When ducts are cut too close to water pipes, it can create unintended leaks and permanent damage, potentially leading to water damage and costly repairs. Disrupting the integrity of the building envelope can affect the overall efficiency of the HVAC system and the comfort of occupants. Ensuring a minimum safe distance between ducts and plumbing lines and using high-quality sealing materials to prevent air and water leaks is crucial. Regular inspections and adherence to industry best practices and building codes help maintain system integrity and prevent issues from escalating into major problems.

Choosing the Right Tools for Cutting Ducts

Selecting the right tools for cutting ducts is essential for precision, safety, and compliance with building codes. Blades and equipment specifically designed for duct materials like aluminum or galvanized steel can significantly reduce the risk of damage and improve cut quality. Matching the blade type to the duct material prevents excessive heat buildup, which can result in blade damage and costly repairs. Using appropriate power settings and durable tools enhance performance, reduce wear and tear, and minimize the frequency of blade replacements and downtime. Regular inspection, maintenance, storage in dry conditions, and keeping tools sharp are vital for maintaining optimal performance. Utilizing dust collection systems and personal protective equipment enhances safety and helps mitigate environmental impact.

FAQs Related to Duct Cutting in HVAC Systems

What are some common mistakes when cutting ducts for HVAC systems?

Common mistakes include the incorrect use of cutting tools, which can lead to jagged edges and weakened sections, and cutting too close to edges or connections, resulting in leaks and increased maintenance costs. Adequate support around the cuts is crucial to prevent stress concentrations and potential failures.What are the best practices for cutting ducts in HVAC installations?

Best practices involve double-checking measurements, using laser-cutting devices and advanced templates, engaging homeowners early in the design phase, and involving HVAC professionals to prevent clashes. Precise cuts and efficient techniques, along with strategic use of guides and templates, are particularly important for tight duct layouts.Why is it important to choose the right tools for cutting ducts?

Selecting the right tools is essential for precision, safety, and compliance with building codes. Blades and equipment specifically designed for duct materials prevent damage and improve cut quality, reduce heat buildup, and minimize wear and tear, ensuring optimal performance and longevity.What are the potential consequences of improper duct cutting for residential plumbing systems?

Improper duct cutting can lead to unintended leaks, permanent damage, and costly water damage. It can also disrupt the building envelope's integrity, affecting system efficiency and occupant comfort. Regular inspections and adherence to industry best practices help maintain system integrity and prevent major issues.What are some safety measures to consider during duct cutting operations?

Safety measures include using appropriate power settings, durable tools, and regular maintenance. Dust collection systems and personal protective equipment (PPE) should be utilized to enhance safety and mitigate environmental impact. Storage of tools in dry conditions and keeping them sharp also contribute to safety and efficiency.

Quick Links

Products

Contact Us