E-mail:Machine@chinaventech.com Expert for pre insulated duct CNC cutting machine.

How Eco-Friendly Practices Cut Duct Board Waste

To cut duct board efficiently and reduce waste, start by precise measurement and marking of cut lines using tools such as laser measurers and straightedges for accurate lines. Scoring the board lightly with a utility knife beforehand helps produce clean cuts. Planning your layout carefully and cutting multiple pieces at once minimizes waste. Overcutting or underestimating lengths often leads to unnecessary material waste, so double-check measurements before cutting. Advanced techniques, such as using templates, can further reduce waste and maintain quality. Eco-friendly materials, like cardboard-based or paper-faced duct boards made from recycled materials, can help reduce waste while maintaining performance. These materials often perform well in both residential and light commercial settings, offering comparable strength and air-tightness to traditional boards, and are certified by organizations like the Forest Stewardship Council for sustainability.

Best Practices for Cutting Duct Board in Construction

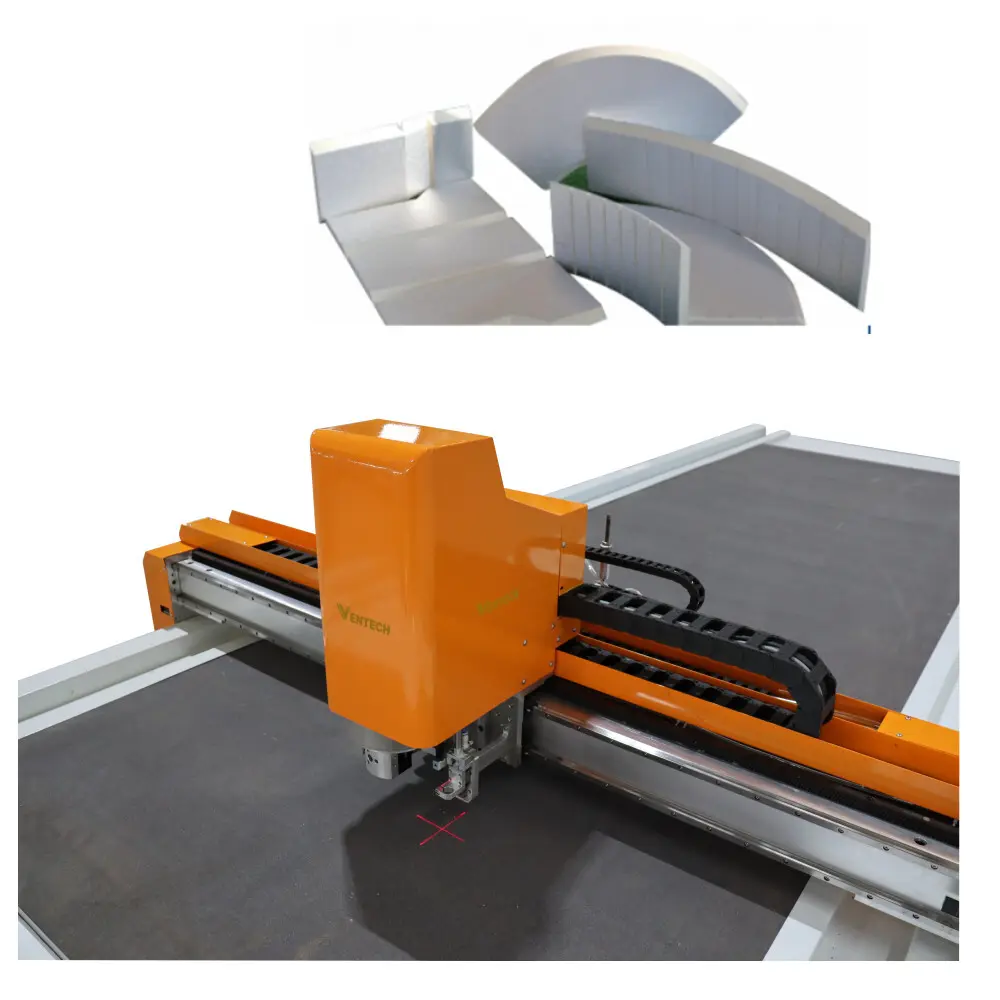

Best practices for cutting duct board in construction focus on minimizing material waste and enhancing environmental sustainability. Accurate planning and the use of advanced technologies, such as 3D modeling and laser cutting, are essential for precise cuts with minimal waste. Employing high-quality, sharp blades and a backing board can further reduce kerf loss. Safety measures, including the use of personal protective equipment such as respirators, and adherence to occupational safety guidelines, are crucial for worker safety. Material selection plays a critical role, with a preference for high-R-value, recycled-content materials certified by organizations like the EPA or FSC. Lifecycle assessments (LCAs) provide a holistic view of a material's environmental impact, guiding choices that favor long-term sustainability. The integration of IoT devices and data analytics in the duct cutting and installation process can significantly enhance precision and efficiency, further reducing waste and improving system performance. Smart technologies, such as smart cutting tables and real-time monitoring sensors, not only ensure precise cuts but also offer valuable data for optimizing duct system performance and reducing environmental impact.

Methods to Minimize Duct Board Waste During Cutting

Methods to minimize duct board waste during cutting involve a multi-faceted approach that leverages advanced technology and sustainable practices. Utilizing laser cutters and detailed cutting plans can significantly reduce material waste, as they ensure precise measurements and efficient usage. Integrating machine learning algorithms into HVAC design software further optimizes duct board material usage by predicting and adjusting design layouts based on real-time data. This approach not only minimizes waste but also enhances the precision of cutting processes. IoT sensors and real-time data monitoring can dynamically adjust cutting procedures, ensuring that material usage aligns with actual project requirements, leading to further reductions in waste. Additionally, employing software like AutoCAD for creating precise duct layout plans can optimize space and minimize material waste. Customizable duct board options from suppliers that cater to specific project needs are also essential, allowing for just-in-time ordering and precise material selection. Predictive analytics, when integrated with these technologies, can forecast material needs, manage inventory more effectively, and automate the cutting process, ensuring minimal waste and efficient resource use.

Eco-Friendly Duct Board Cutting Techniques for Commercial Buildings

Eco-friendly duct board cutting techniques, such as laser cutting and the use of computer-aided design (CAD) software, play a crucial role in reducing material waste and enhancing the overall sustainability of commercial buildings. By enabling precise planning and real-time adjustments, these methods significantly improve the efficiency of ductwork installation, minimizing waste by up to 30%. Furthermore, they contribute to improved energy efficiency and indoor air quality, as seen in case studies where buildings have reduced energy consumption by 15% and improved air circulation by up to 20%. The integration of these techniques with high-efficiency HVAC systems and advanced insulation not only complements these benefits but also boosts water efficiency and reduces maintenance costs. For example, optimized ductwork and efficient plumbing systems have been shown to decrease water usage by 20% and lower maintenance by 25%. These practices enhance a building's durability and resilience, reducing structural stress and ensuring the HVAC system remains energy-efficient over time. As regulations increasingly mandate the use of these sustainable practices, they are becoming not just beneficial but also a requirement for new construction and renovations.

Minimizing Duct Board Waste in Cutting

Minimizing duct board waste during the cutting process is a critical aspect of achieving sustainable and efficient HVAC installations. By employing advanced software tools for layout optimization and using modular designs, contractors can significantly reduce material surplus. Integrating technological solutions such as IoT sensors and BIM platforms further enhances precision and real-time monitoring, leading to even greater waste reduction. Collaborative efforts with suppliers to develop sustainable materials and implement lean manufacturing techniques also play a vital role in reducing overall waste. Blockchain technology can improve supply chain transparency and traceability, ensuring that materials maintain high sustainability standards from production to installation. Remote monitoring and predictive maintenance systems can optimize operations, ensuring both efficiency and longevity, thereby reducing waste in the long term.

Effects of Cutting Duct Board on Energy Efficiency

The effects of cutting duct board on energy efficiency are significant. Precise cutting and the use of advanced techniques, such as computer-aided design and laser cutting, are crucial in minimizing material waste and enhancing the airtightness of duct systems. A well-sealed system reduces air leaks, improving overall energy efficiency by ensuring conditioned air reaches its intended destinations with minimal loss. Smart sensors and machine learning algorithms further optimize energy usage by monitoring and adjusting HVAC performance based on real-time data, leading to substantial reductions in energy waste and maintenance costs. These advancements enhance sustainability and provide homeowners with comfortable and energy-efficient living environments.

Tips for Accurate Cutting of Duct Board

To ensure accurate duct board cutting, start with the right materials and procedures. High-density duct board provides a durable foundation, reducing waste. Precision begins with proper measurement, where calipers and ultrasonic thickness gauges identify thickness inconsistencies early. Marking the material with chalk lines aids alignment and prevents overshooting. Regular calibration of measuring tools ensures accuracy. Advanced cutting tools like laser cutters can significantly enhance precision. Comprehensive pre-cutting inspections through visual checks and detailed marking identify material variations. Regular maintenance and calibration of cutting tools, combined with consistent training for the workforce, effectively handle material thickness inconsistency. Quality control measures, including detailed checklists and supplier feedback, ensure consistent material quality throughout the process.

FAQs Related to Reducing Duct Board Waste and Enhancing Sustainability in Construction

What are some best practices for cutting duct board to reduce waste during construction?

Best practices include precise measurement and marking, using tools such as laser measurers and straightedges, scoring the board lightly with a utility knife, planning the layout carefully, and cutting multiple pieces at once to minimize waste. Advanced techniques like using templates and eco-friendly materials that are recycled and sustainably sourced can also help reduce waste and maintain quality.How can laser cutting and computer-aided design (CAD) software contribute to reducing duct board waste and improving sustainability in commercial buildings?

Laser cutting and CAD software enable precise planning and real-time adjustments, reducing material waste by up to 30%. They also enhance energy efficiency and indoor air quality, as seen in case studies where buildings have reduced energy consumption by 15% and improved air circulation by up to 20%. Integrating these techniques with high-efficiency HVAC systems can further boost water efficiency and reduce maintenance costs.What methods can be used to minimize duct board waste during the cutting process?

Methods include utilizing laser cutters and detailed cutting plans, integrating machine learning algorithms into HVAC design software for optimal material usage, using IoT sensors and real-time data monitoring for dynamic adjustments, employing software like AutoCAD for precise duct layout planning, and opting for customizable duct board options from suppliers that cater to specific project needs.What are the key factors in accurately cutting duct board to ensure efficiency and quality?

Key factors include the use of high-quality, sharp blades and a backing board to reduce kerf loss, and the employment of safety measures such as personal protective equipment and adherence to occupational safety guidelines. Precision is also achieved through the use of advanced tools like laser cutters and calipers for detailed measurements and regular calibration of tools to handle material thickness inconsistency.How does cutting duct board accurately impact the energy efficiency of a building?

Accurate cutting enhances the airtightness of duct systems by reducing air leaks, which improves energy efficiency by ensuring conditioned air reaches its intended destinations with minimal loss. Smart sensors and machine learning algorithms further optimize energy usage by monitoring and adjusting HVAC performance based on real-time data, which can lead to substantial reductions in energy waste and maintenance costs.

Quick Links

Products

Contact Us