E-mail:Machine@chinaventech.com Expert for pre insulated duct CNC cutting machine.

How Foam Cutter Factories Can Improve Your Business Efficiency

Efficient operations in foam cutter factories encompass several key areas, including material handling, cutting precision, and finishing touches. Effective material handling reduces setup times and minimizes losses during transfer, while advanced cutting software optimizes material usage through precise layout planning and waste reduction. Automations, such as robotic arms and autonomous guided vehicles (AGVs), further enhance production speed and accuracy. Regular maintenance of equipment and ongoing training for operators are crucial for maintaining high-quality outputs. These practices, combined with strategic supplier relationships and sustainable practices, contribute to a streamlined and environmentally friendly factory operation.

Challenges in Foam Cutting Operations

Challenges in foam cutting operations are multifaceted and interrelated. Variations in foam density, thickness, and material quality can significantly impact cutting precision and efficiency, leading to product inconsistencies and higher scrap rates. Maintaining precise cuts becomes particularly difficult with uneven surfaces and material inconsistencies. To address these challenges, manufacturers implement advanced quality control measures and utilize predictive analytics and machine learning algorithms for predictive maintenance, ensuring optimal machinery performance. Real-time monitoring systems track material consistency and adjust cutting parameters, thereby reducing downtime and waste.

Latest Foam Cutting Technology Trends

The latest foam cutting technologies, such as laser and waterjet cutting, are transforming the manufacturing landscape. These methods reduce material waste and processing times, leading to improved product quality and enhanced production speed. Advanced waterjet cutting excels for intricate designs and soft materials, providing clean cuts with minimal heat damage. Laser cutting ensures highly precise cuts, allowing for complex patterns and shapes. Coupled with sophisticated software for real-time adjustments and monitoring, these technologies streamline operations, enabling flexible responses to market demands. Automation and data analytics further optimize workflow, reducing downtime and labor costs.

Successful Improvements in Foam Cutting Factory Operations

Successful improvements in foam cutting factory operations have been driven by the integration of advanced machinery, data analytics, and robust training programs. New technologies enhance production efficiency by reducing setup times and increasing cutting accuracy, leading to faster delivery and higher quality products. Quality control is crucial, with tiered training programs and hands-on sessions ensuring operators can adapt to new equipment effectively. Automated systems and AI provide real-time data for predictive maintenance and energy efficiency, reducing operational costs and environmental impact. By leveraging data analytics, factories monitor key performance indicators, identify inefficiencies, and implement continuous improvements, driving market competitiveness and customer satisfaction.

Best Practices for Foam Cutting in Factories

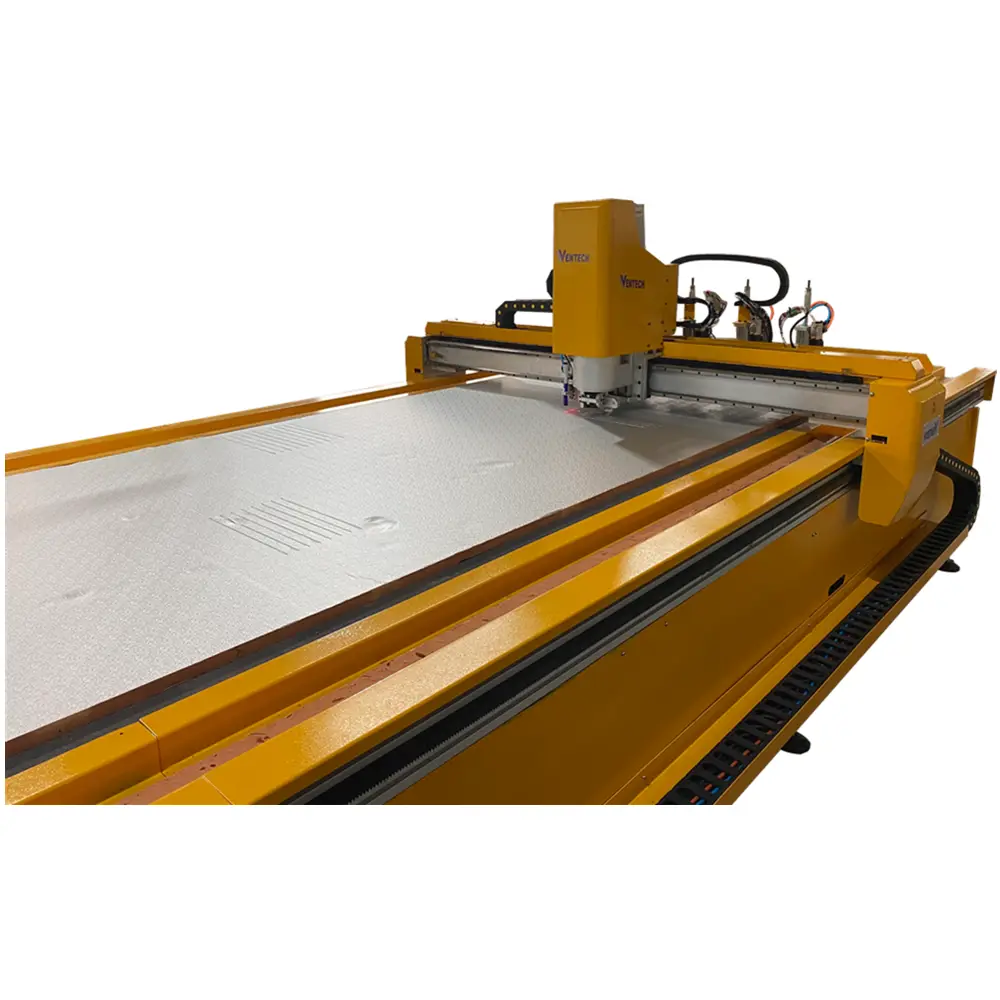

Best practices for foam cutting in factories involve integrating advanced technologies to enhance efficiency and accuracy. Utilizing CNC foam cutters with advanced software integration significantly reduces setup times and enhances precision. Laser cutting technology offers faster cutting speeds and superior quality finishes. Robust maintenance routines and optimized material handling processes minimize downtime and improve workflow. Techniques like spacer methods, advanced design software for better material layouts, and hexagonal packing algorithms efficiently use leftover pieces, reducing waste and savings costs. Continuous improvement strategies, including regular training sessions and iterative process refinements, help maintain and enhance efficiency consistently over time.

Techniques to Extend Foam Cutter Efficiency

Techniques to extend foam cutter efficiency include leveraging advanced technologies and optimizing operational practices. CNC foam cutters with software integration reduce setup times and enhance precision. Laser cutting technology offers faster cutting speeds and high-quality finishes. Investing in robust maintenance routines and refined material handling processes minimize downtime and improve workflow. Spacer techniques, advanced design software for material layouts, and hexagonal packing algorithms efficiently use leftover pieces. Continuous improvement strategies, such as regular training sessions and iterative process refinements, help maintain and enhance efficiency.

Future Trends in Foam Cutting Technology

Future trends in foam cutting technology are revolutionizing the industry with enhanced automation and sustainability. The integration of artificial intelligence and machine learning leads to more precise cuts and reduced waste, improving operational efficiency. Robotic systems and IoT technologies further automate processes, reducing error rates and providing real-time data analysis. Sustainability initiatives, such as recycled materials and energy-efficient cutting heads, are gaining momentum. Digital twins and simulations offer real-time process optimization and predictive maintenance, significantly reducing material waste and energy consumption. As regulatory frameworks emphasize sustainability and digital transformation, foam cutting factories are adopting innovative solutions like blockchain technology for transparent and secure supply chains.

These advancements not only enhance operational efficiency but also promote sustainable practices, ensuring environmental responsibility and future-proofing the industry.

FAQs Related to Foam Cutting Operations and Technology

How can foam cutter factory operations improve efficiency?

Efficient operations in foam cutter factories can be improved by reducing setup times, optimizing material usage, enhancing cutting precision through advanced software, and using automation technologies like robotic arms and AGVs. Regular maintenance and ongoing training for operators are also crucial to maintain high-quality outputs.What are the challenges faced in foam cutting operations?

Challenges in foam cutting operations include variations in foam density and material quality, which impact cutting precision and efficiency. Addressing these challenges requires implementing advanced quality control measures, real-time monitoring, and predictive analytics for predictive maintenance.What are the latest trends in foam cutting technology?

The latest foam cutting technologies include laser and waterjet cutting, which reduce waste and processing times. Advanced software for real-time adjustments and monitoring, combined with automation and data analytics, streamline operations and enable flexible responses to market demands.What are some best practices for foam cutting in factories?

Best practices include integrating advanced machinery like CNC foam cutters, utilizing laser cutting technology for precision, maintaining robust routines, and optimizing material handling processes. Continuous improvement strategies, such as regular training and iterative process refinements, help enhance efficiency consistently.What are the future trends in foam cutting technology?

Future trends include the integration of AI and machine learning for more precise cuts and reduced waste, automation with robotic systems and IoT technologies, and sustainability initiatives like recycled materials and energy-efficient cutting heads. Digital twins and simulations offer real-time process optimization and predictive maintenance, reducing material waste and energy consumption.

Quick Links

Products

Contact Us