E-mail:Machine@chinaventech.com Expert for pre insulated duct CNC cutting machine.

Technological Leaders Among Best Foam Cutter Manufacturers

Among the best foam cutter manufacturers, companies are increasingly focusing on enhancing precision and sustainability. Innovations in laser cutting technology are allowing for higher precision while significantly reducing material waste. The integration of AI and automation is also a key trend, with many manufacturers developing intelligent cutting paths and energy-efficient systems. These advancements are aimed at not only improving operational efficiency but also aligning with the growing demand for eco-friendly solutions. To cater to the needs of various-sized businesses, manufacturers are streamlining user interfaces and offering customizable packages, along with financing options, to ensure cost-effectiveness. Real-time feedback and predictive maintenance features are further enhancing reliability and reducing downtime, contributing to a more efficient and sustainable production process. Data analytics tools, such as Predix and Azure IoT, are critical in optimizing foam cutting operations and improving overall performance metrics.

Top Foam Cutter Brands with High-Quality Solutions

Among the top foam cutter brands, manufacturers often prioritize high-quality solutions that offer precision, efficiency, and sustainability. Brands such as Enco and Grav offer user-friendly interfaces and portability, making them ideal for both professional and small business applications. Roland and Dremel are highly regarded for their robust features and precision needed for complex projects. These brands have successfully adopted advanced technologies such as automated nesting software and digital tools to reduce waste and improve material usage. They also collaborate with suppliers to source eco-friendly materials and implement recycling programs, further enhancing their commitment to sustainability.

Leading Foam Cutting Companies and Their Innovations

Leading foam cutting companies are at the forefront of innovation, constantly striving to push the boundaries of what is possible. They have embraced advanced technologies such as laser cutting with real-time feedback systems to achieve higher precision and efficiency, leading to reduced material waste and faster turnaround times. These companies are increasingly focusing on sustainability by implementing strategies such as using recycled foams, optimizing energy usage, and exploring sustainable laser technologies and renewable energy sources. The shift towards circular business models, where the emphasis is on product longevity and recycling, further enhances their environmental efforts. Companies are also leveraging smart technologies like IoT and AI for real-time monitoring, predictive maintenance, and data-driven optimizations, which align with the growing demand for eco-friendly products from environmentally conscious consumers.

Best Foam Cutting Machines for Various Applications

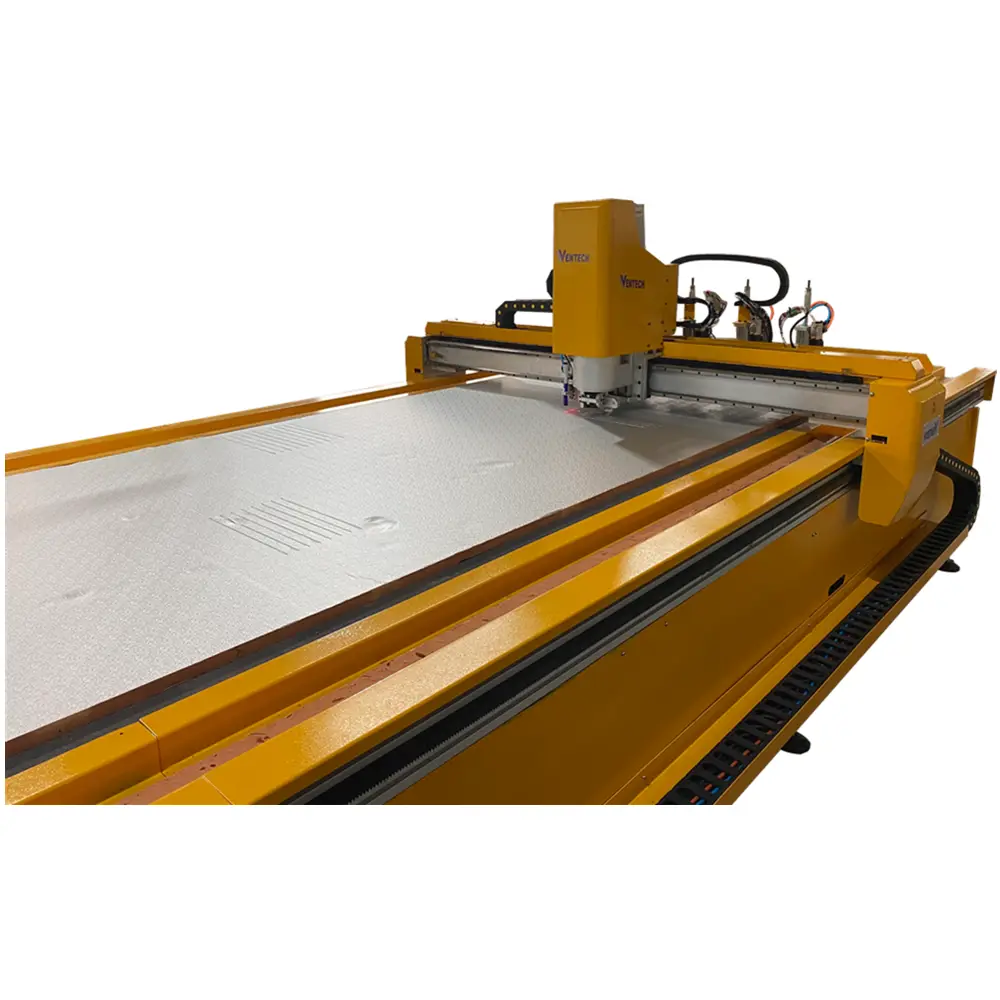

Best foam cutting machines for various applications are recognized for their precision, efficiency, and adaptability. Advanced CNC control systems, laser cutting, waterjet cutting, and thermal cutting methods enhance user experience by providing precise controls and intuitive interfaces. These innovations improve production efficiency through faster cutting speeds, reduced material waste, and automated workflow management, while ensuring consistent quality and minimizing manual errors. For instance, laser cutting offers high accuracy for intricate designs, making it valuable in automotive interior design. CNC technology ensures consistent quality and reduces manual errors, supporting large-scale production. Combining real-time monitoring and intelligent process planning further enhances efficiency and quality, ensuring optimal performance and sustainability in the manufacturing process.

Eco-Friendly Foam Cutter Factories

Eco-friendly foam cutter factories are at the forefront of a growing trend towards sustainability. By adopting advanced laser cutting technologies and renewable energy sources, these factories significantly reduce their environmental impact while maintaining or even enhancing production performance. Collaborative efforts with supply chain partners are crucial for maintaining these sustainable practices throughout the lifecycle of products, from sourcing biodegradable foams to recycling programs. Manufacturers can drive innovation by partnering with research institutions and technology companies, developing techniques and materials that align with eco-friendly goals. Effective communication of these efforts through clear and compelling messaging, supported by case studies and real-world examples, builds trust with customers and stakeholders. Digital tools such as IoT sensors and real-time monitoring can further optimize resource use and reduce waste, making sustainability a core aspect of operational excellence.

Recommendations for Choosing the Best Foam Cutter

When selecting the best foam cutter, consider these key factors:

* Material characteristics: Ensure the cutter can handle the foam density and thickness effectively.

* Project complexity: Choose a cutter with adjustable settings for optimal results on intricate designs.

* Software compatibility and design: Advanced software such as AutoCAD or Laser Cut offers real-time simulations and parametric design.

* Environmental impact and sustainability: Evaluate energy efficiency and waste production. Laser cutters are generally more energy-efficient.

* Safety and maintenance: Ensure the cutter meets safety standards and regular maintenance is adhered to for a safe working environment.

FAQs Related to Foam Cutter Technology and Sustainability

What technologies are foam cutter manufacturers adopting to enhance sustainability and precision?

Foam cutter manufacturers are adopting laser cutting technology for higher precision and reduced material waste. They are also integrating AI and automation to develop intelligent cutting paths and energy-efficient systems, aligning with the demand for eco-friendly solutions.Which foam cutter brands are known for their high-quality solutions and user-friendly interfaces?

Brands such as Enco and Grav are known for their high-quality solutions and user-friendly interfaces, making them ideal for both professional and small business applications. Roland and Dremel are also highly regarded for their robust features and precision for complex projects.How are leading foam cutting companies advancing towards sustainability?

Leading foam cutting companies are adopting advanced technologies like laser cutting with real-time feedback systems, using recycled foams, optimizing energy usage, and exploring sustainable laser technologies and renewable energy sources. They are also embracing circular business models and leveraging smart technologies like IoT and AI for real-time monitoring and predictive maintenance.What factors should be considered when choosing the best foam cutter?

When selecting the best foam cutter, consider factors such as material characteristics, project complexity, software compatibility and design, environmental impact and sustainability, and safety and maintenance. Ensure the cutter can handle the foam density and thickness effectively and meets safety standards for a safe working environment.What are some eco-friendly practices in foam cutter factories?

Eco-friendly foam cutter factories adopt advanced laser cutting technologies and renewable energy sources to reduce their environmental impact. They also collaborate with supply chain partners for sustainable practices, develop eco-friendly materials, and implement recycling programs. Moreover, they use digital tools like IoT sensors and real-time monitoring to optimize resource use and reduce waste, making sustainability a core aspect of operational excellence.

Quick Links

Products

Contact Us