E-mail:Machine@chinaventech.com Expert for pre insulated duct CNC cutting machine.

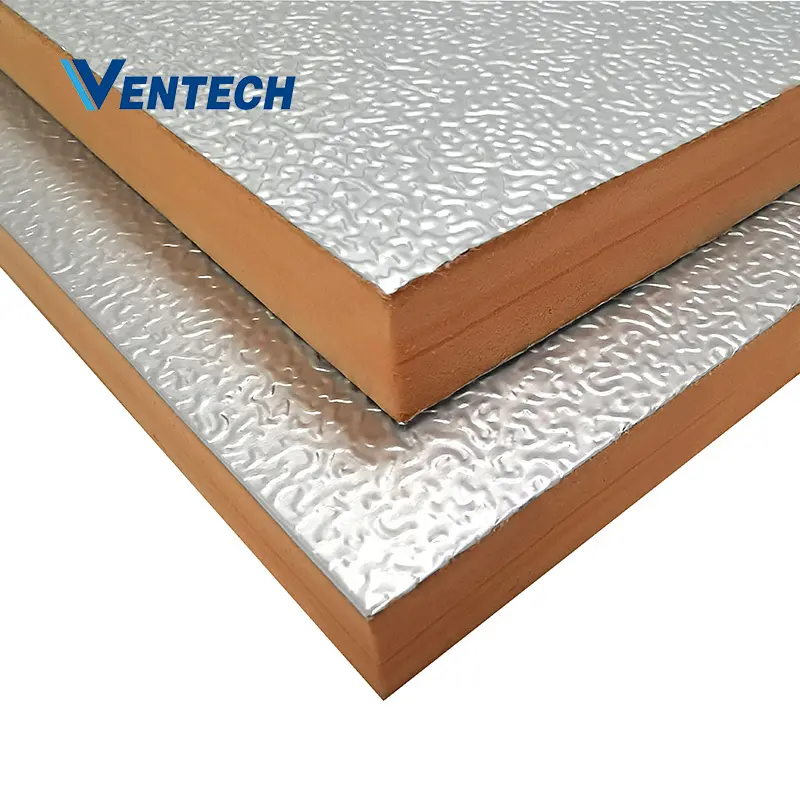

What to Look for in Pre-Insulated Phenolic Ducts for Industrial Use

Pre-insulated phenolic ducts offer several key advantages for industrial applications. They enhance energy efficiency by providing high R-values and low thermal conductivity, which significantly reduce heat loss and gain, leading to substantial energy savings and improved operational costs. Additionally, their tight seals and minimal air gaps minimize heat transfer and air leakage, ensuring cleaner and more controlled airflow, thereby improving indoor air quality. The durable design of these ducts further contributes to reduced maintenance, as they are resistant to moisture, mold, and mildew, ensuring long-lasting performance and reliability. Moreover, they easily meet or exceed stringent standards like LEED and ASHRAE 90.1, ensuring easy compliance and eligibility for energy efficiency certifications. For specific industries, such as food processing and pharmaceuticals, pre-insulated phenolic ducts can be customized with advanced filtration systems and adaptive control technologies to meet unique needs.

Evaluating the Durability and Environmental Impact of Phenolic Ducts

The evaluation of phenolic ducts' durability and environmental impact involves a multifaceted approach. Phenolic ducts are highly durable in harsh industrial environments and can withstand extreme temperatures with minimal degradation. Manufacturers use high-quality, eco-friendly materials that meet rigorous environmental standards, such as UL, CE, and ISO certifications, ensuring safety and quality while minimizing environmental impact. Lifecycle assessments highlight that using recycled materials significantly reduces the environmental footprint, and implementing green manufacturing processes further enhances sustainability. Performance testing under various conditions ensures long-term durability and energy efficiency. Advanced monitoring and maintenance solutions also help prevent potential issues, extending the lifecycle and optimizing performance. Moreover, advanced sorting technologies and circular economy practices improve material recovery and reduce waste, contributing to a more sustainable supply chain.

Advanced Manufacturing Technologies in Pre-Insulated Phenolic Ducts

Advanced manufacturing technologies in pre-insulated phenolic ducts have revolutionized industrial applications by enhancing thermal efficiency and durability. These technologies enable precise insulation layer application and use high-strength materials to achieve superior thermal barriers, leading to substantial energy savings and reduced maintenance costs. Automated production processes ensure consistent quality and compliance with stringent standards, improving overall system reliability and extending service life. Case studies in diverse industries, such as HVAC, petrochemicals, and food processing, demonstrate significant benefits, including a 20% reduction in energy consumption in petrochemical plants and a 15% decrease in maintenance costs in manufacturing facilities. These advanced ducts also offer enhanced safety features, aligning with stringent ATEX and IECEx standards, ensuring compliance with regulatory requirements. Integrating IoT and AI technologies further optimizes energy consumption, predicts maintenance needs, and ensures continuous compliance monitoring, making them a valuable investment for industrial operations.

Applications and Uses in HVAC Systems

Pre-insulated phenolic ducts are highly effective in HVAC systems due to their ability to maintain precise temperature and humidity levels. In industrial settings, they minimize leaks and ensure thermal efficiency, reducing energy consumption and extending equipment lifespan. They excel in pharmaceutical and healthcare facilities by providing a clean, sterile environment that is easy to maintain and clean, minimizing the risk of contamination. In solar farms, phenolic ducts manage temperature gradients, improving solar panel efficiency and reducing heat build-up. In wind turbine maintenance shops, these ducts handle moisture, dust, and mechanical stress, ensuring reliable HVAC performance even in harsh outdoor conditions. The thermal insulation performance, durability, and ease of installation make phenolic ducts a preferred choice for various challenging environments, enhancing the overall efficiency and reliability of HVAC systems.

Challenges and Best Practices in Integration

Challenges in integrating pre-insulated phenolic ducts into industrial HVAC systems include ensuring data consistency and addressing specific issues related to data formats and types. Best practices involve implementing standardized data models, using ETL tools for automation, and establishing clear data governance policies. Middleware solutions like Apache NiFi or MuleSoft help manage complex data flows, while API standards such as REST and gRPC enhance seamless data exchange. Security and compliance are also crucial, requiring robust measures like encrypted data transfers, access controls, and regular security audits, especially when adhering to standards like GDPR and HIPAA. Edge computing can significantly improve data processing and real-time decision-making, although managing hardware reliability and ensuring secure data transmission remain critical challenges. Machine learning can further enhance security and compliance by providing real-time anomaly detection and threat analysis, although it necessitates high-quality training datasets and addresses issues related to data quality.

Vendor Reliability and Supply Chain

Vendor reliability and supply chain management are critical for ensuring consistent operations and minimizing disruptions in industrial facilities. Companies prioritize vendors based on their reliability in deliveries, quality control measures, and responsiveness to issues. The integration of advanced technologies like IoT and AI enhances supply chain visibility, enabling real-time monitoring and predictive maintenance. Shared platforms and standardized protocols foster better collaboration and information sharing, leading to a more transparent and responsive network. Sustainability practices, such as sourcing recycled materials and optimizing energy use, further support operational efficiency and environmental responsibility. By adopting these strategies, industrial facilities can build robust, sustainable supply chains that can withstand the complexities of today's business environment.

Quick Links

Products

Contact Us