E-mail:Machine@chinaventech.com Expert for pre insulated duct CNC cutting machine.

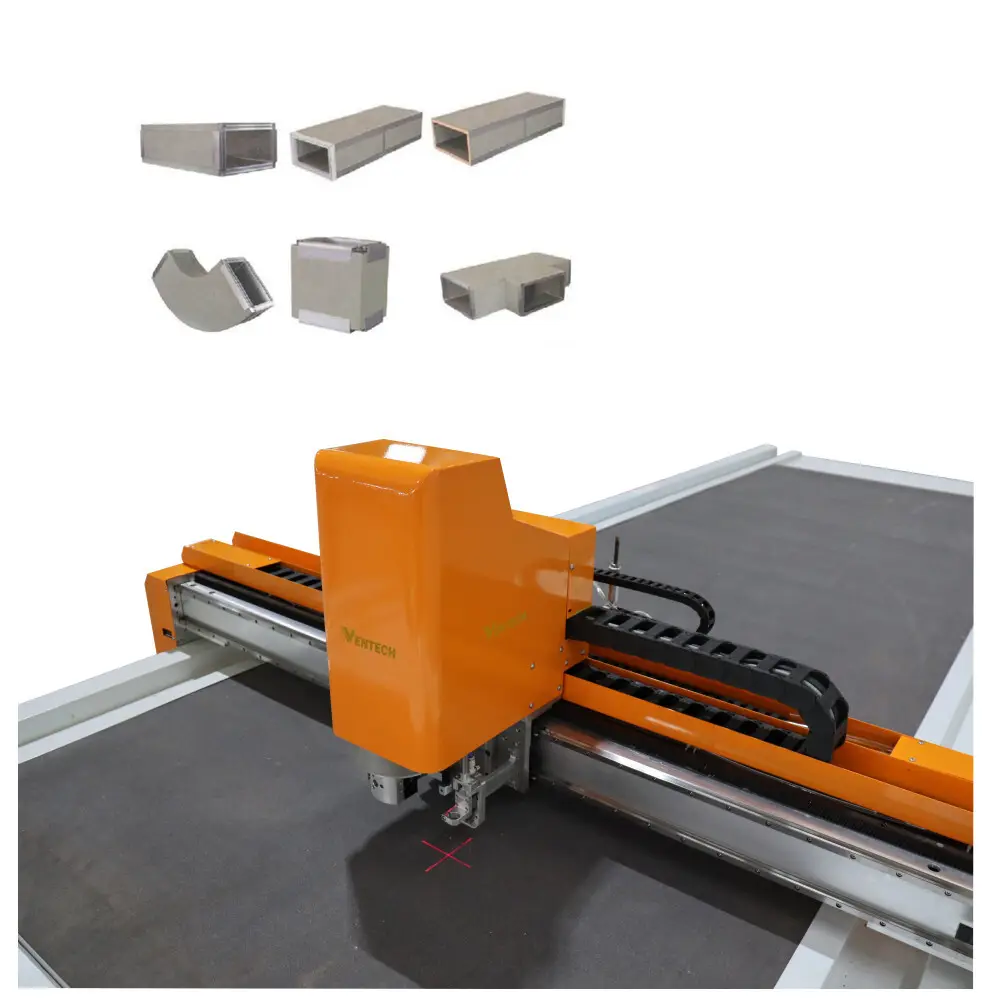

What is the Most Durable Pre-Insulated Duct Cutter?

Pre-insulated duct cutters are essential tools in the HVAC industry, providing precise and efficient cuts in ductwork to ensure a tight and airtight seal. These cutters are typically made from either stainless steel or high-grade aluminum, each material offering distinct advantages based on the application environment. Stainless steel cutters are superior in industrial and harsh outdoor settings due to their superior corrosion resistance and long-term reliability. In contrast, high-grade aluminum cutters are better suited for residential installations, offering lighter weight, greater flexibility, and easier installation.

The choice of material significantly influences performance characteristics. Stainless steel cutters are more robust in damp or corrosive conditions, whereas aluminum cutters offer quicker and more straightforward work processes. Advanced features, such as flame-retardant and anti-static properties, enhance both the safety and longevity of HVAC systems, leading to improved energy efficiency, reduced maintenance costs, and enhanced indoor air quality.

When comparing pre-insulated duct cutters to traditional ducting methods, the former emerges as a more durable and efficient solution. Pre-insulated duct cutters are designed with reinforced blade technology and integrated insulation, providing enhanced resistance to frequent use and harsh environmental conditions. This material strength ensures longer service life and reduces the likelihood of air leaks, thereby improving system efficiency and minimizing downtime. Traditional ducting methods, relying on tape, mastic, and gaskets for sealing, can be less consistent, leading to a higher risk of leaks and requiring more frequent replacements.

Key Materials and Manufacturing Processes

Heres a quick guide to the key materials and manufacturing processes used in duct cutters, each bringing its own benefits:

- Ceramic composites Robust and highly resistant to extreme temperatures, corrosion, and wear, offering unmatched durability. Advanced materials require specialized manufacturing but result in long-term cost savings through reduced maintenance and extended service life.

- Stainless steel Known for its excellent corrosion resistance, durability, and longevity, making it a popular choice for environments with harsh conditions. Advanced manufacturing techniques enhance precision, speed, and efficiency.

- High-temperature alloys Designed for extreme conditions, these alloys offer superior strength and durability at elevated temperatures, often used in demanding industrial settings. Sophisticated manufacturing processes ensure precise cutting and minimal waste.

- Interchangeable blades Versatile and easy to replace, enabling the cutter to handle different materials and thicknesses efficiently. Advanced insert technology ensures uniform cutting and reduces the need for frequent replacements, enhancing overall performance and longevity.

- Automated systems Incorporating advanced robotic cutters and AI-powered predictive maintenance, these systems increase precision, reduce material waste, and extend the lifecycle of the cutters. The integration of these technologies leads to improved efficiency and cost-effectiveness across various applications.

Best Practices and Pro Recommendations for Installation

Heres a guide to the best tools and practices for pre-insulated duct cutting:

- High-quality PVC and metal cutters Opt for Ridgid or theapolis models, known for their durability and precision, to ensure the integrity of the ducts.

- Regular inspection and maintenance Sharply maintained cutters reduce the risk of damage and enhance efficiency. Check for wear and replace worn or dull blades immediately.

- Proper storage Store cutters in a dry area to prevent rust and corrosion, and organize them with clear tags for easy access. A well-organized space minimizes the risk of accidental damage.

- Utilize rust inhibitors Apply Zinsser Bin or similar rust inhibitors after use to protect metal cutters in humid environments. This helps maintain their longevity and functionality.

- Digital tracking systems Use digital tools like FSM software to log maintenance tasks and ensure nothing is missed, promoting a culture of responsibility and efficiency.

Advantages and Challenges of Pre-Insulated Duct Cutters

Heres a guide to the advantages and challenges of pre-insulated duct cutters:

- Durability Made with high-strength, corrosion-resistant materials that ensure longevity in varied environments, critical for HVAC systems.

- Insulation Efficiency Advanced insulation maintains HVAC system efficiency, reducing energy waste and improving overall performance.

- Ease of Installation Modular design and customizable options allow for precise fitting and minimal waste, streamlining the installation process.

- Environmental Impact Some models use eco-friendly materials and processes, reducing the environmental footprint through the use of recycled or biosourced components.

- Maintenance High-quality coatings withstand extreme mechanical stress, but regular maintenance is required to ensure continued performance and longevity, especially in harsh conditions.

This comprehensive guide ensures you choose the most durable and efficient pre-insulated duct cutter for your HVAC needs.

FAQs Related to Pre-Insulated Duct Cutters

What are the advantages of using pre-insulated duct cutters over traditional ducting methods?

Pre-insulated duct cutters are more durable and efficient, reducing the likelihood of air leaks, improving system efficiency, and minimizing downtime. They also offer enhanced resistance to frequent use and harsh environmental conditions, leading to longer service life and improved energy efficiency.What are the key materials used in pre-insulated duct cutters, and what are their benefits?

Key materials include stainless steel for superior corrosion resistance in harsh environments, high-temperature alloys for extreme conditions, and ceramic composites for high-temperature and wear resistance. These materials enhance durability, precision, and efficiency.What is the most durable material for pre-insulated duct cutters, and in what settings is it best used?

Stainless steel is the most durable material, offering superior corrosion resistance in industrial and harsh outdoor settings. High-grade aluminum is better for residential installations, providing lighter weight, flexibility, and easier installation.How can regular inspection and maintenance of pre-insulated duct cutters improve their longevity?

Regular inspection and maintenance, including replacing worn or dull blades, reduce the risk of damage and enhance the overall performance and longevity of pre-insulated duct cutters. It also ensures consistent and efficient duct cutting.What are the main challenges of using pre-insulated duct cutters, and how can they be addressed?

Challenges include the necessity for regular maintenance, proper storage to prevent rust and corrosion, and the potential need for specialized tools and training. These can be addressed by utilizing rust inhibitors, storing cutters in a dry area, and training staff on proper care and maintenance.

Quick Links

Products

Contact Us