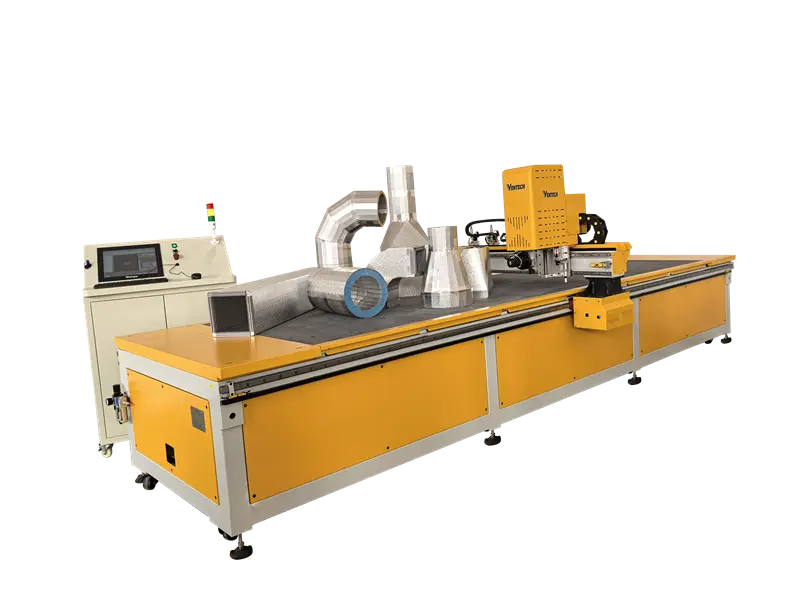

E-mail:Machine@chinaventech.com Expert for pre insulated duct CNC cutting machine.

What is the Energy Efficiency of Pre-Insulated Duct?

Pre-insulated ducts offer significant benefits in energy efficiency, HVAC system performance, and overall building aesthetics. These ducts can provide up to a 20-30% reduction in energy consumption, which translates to lower operational costs and a reduced environmental impact. Proper insulation not only maintains consistent air temperature and pressure but also helps reduce the load on HVAC equipment, thereby enhancing system performance. Additionally, pre-insulated ducts can reduce the need for oversized HVAC equipment by 25% or more, as observed in one commercial construction project. This reduction in size leads to better energy efficiency and lower lifecycle costs.

Insulated ducts also prevent condensation and moisture accumulation, which improves indoor air quality and helps protect the duct system and surrounding structures. This moisture control contributes to better building aesthetics, as proper installation and design can integrate pre-insulated ducts seamlessly into the building's architecture, creating a more harmonious and streamlined appearance.

Energy Efficiency in Pre-Insulated Ducts

The energy efficiency of pre-insulated ducts is a critical factor in modern green building design. These duct systems provide uniform insulation coverage and higher insulation values, which help reduce heat loss or gain. Studies show that pre-insulated ducts can reduce heating and cooling costs by up to 30%, with many projects experiencing a 20% reduction within the first year. While the initial expense of pre-insulated ducts can be higher, detailed cost-benefit analyses indicate a significant return on investment through long-term energy savings. Proper installation is essential, involving gap-free joints, comprehensive training for installers, and the use of tools like infrared thermography. Regular quality control measures, such as visual inspections and pressure tests, ensure seal integrity and system efficacy. Innovative materials, such as phase change materials and advanced insulation technologies, further enhance thermal performance. Integrating these ducts with smart building systems can optimize energy efficiency even further.

Comparing Pre-Insulated Ducts to Standard Duct Systems

Pre-insulated ducts offer a range of advantages over standard duct systems, particularly in terms of energy efficiency. By using continuous factory-applied insulation, these ducts significantly reduce heat loss and gain, leading to substantial energy savings. This insulation also improves the lifecycle cost and maintenance requirements of HVAC systems by minimizing the need for additional insulation and sealing. Real-world applications demonstrate that pre-insulated ducts maintain consistent indoor temperatures and better control humidity levels, enhancing occupant comfort. When integrated with renewable energy sources and smart HVAC systems, these ducts further optimize energy efficiency and environmental impact, providing a comprehensive approach to sustainable building design. While initial considerations like weight and manufacturing energy use are important, the long-term benefits in terms of reduced energy consumption and maintenance costs make pre-insulated ducts an optimal solution for modern construction projects.

Environmental Impact of Pre-Insulated Ducts

Pre-insulated ducts significantly reduce energy loss in HVAC systems by maintaining consistent air temperature and pressure within the ductwork. This leads to lower overall energy consumption, especially in colder climates where maintaining optimal indoor conditions is crucial. Studies show that adopting pre-insulated ducts can reduce energy consumption by up to 20%. However, in warmer regions, the effectiveness is slightly diminished due to solar heat gain, which can impact their efficiency. Lifecycle analyses support the environmental benefits by highlighting substantial long-term energy savings and reduced maintenance costs, although managing the effects of solar exposure on material durability is necessary.

Installation Advantages and Challenges

Installation of pre-insulated ducts comes with several advantages, including enhanced energy efficiency, a quicker installation process, and reduced risk of insulation damage. By reducing heat loss or gain, these ducts contribute to lower HVAC system loads and improved comfort levels. The rapid installation process helps speed up construction timelines and reduces labor costs. Properly sealed and factory-insulated sections minimize the risk of damage during transport and installation, ensuring the integrity of the insulation throughout the duct's lifecycle. However, there are also challenges, such as the necessity for careful handling and proper storage to maintain the ducts insulation properties. Ensuring a conducive storage environment is crucial to prevent contamination or physical damage. Additionally, the higher initial costs of pre-insulated ducts compared to traditional methods can be offset by long-term energy savings and lifecycle cost analysis. Careful financial planning is essential to balance this initial investment against long-term benefits.

FAQs Related to Pre-Insulated Ducts

What are the main benefits of using pre-insulated ducts?

Pre-insulated ducts offer significant benefits in energy efficiency, HVAC system performance, and overall building aesthetics. They can provide up to a 20-30% reduction in energy consumption, leading to lower operational costs and a reduced environmental impact. Proper insulation also helps maintain consistent air temperature and pressure, which improves indoor air quality and reduces the load on HVAC equipment. Additionally, they can integrate seamlessly into the building's architecture, enhancing its aesthetics.How do pre-insulated ducts reduce energy consumption in HVAC systems?

Pre-insulated ducts reduce energy consumption by providing uniform insulation coverage and higher insulation values, which help reduce heat loss or gain. This results in lower HVAC system loads and improved overall energy efficiency. Studies show that pre-insulated ducts can reduce heating and cooling costs by up to 30%, with many projects experiencing a 20% reduction within the first year.What are the challenges in the installation of pre-insulated ducts?

Installation challenges include the need for careful handling and proper storage to maintain the ducts insulation properties. Ensuring a conducive storage environment is crucial to prevent contamination or physical damage. Additionally, the higher initial costs of pre-insulated ducts compared to traditional methods can be offset by long-term energy savings and lifecycle cost analysis. Careful financial planning is essential to balance this initial investment against long-term benefits.How do pre-insulated ducts compare to standard duct systems in terms of energy efficiency?

Pre-insulated ducts offer a range of advantages over standard duct systems, particularly in terms of energy efficiency. By using continuous factory-applied insulation, these ducts significantly reduce heat loss and gain, leading to substantial energy savings. This insulation also improves the lifecycle cost and maintenance requirements of HVAC systems by minimizing the need for additional insulation and sealing. Real-world applications demonstrate that pre-insulated ducts maintain consistent indoor temperatures and better control humidity levels, enhancing occupant comfort.What is the environmental impact of pre-insulated ducts?

Pre-insulated ducts significantly reduce energy loss in HVAC systems by maintaining consistent air temperature and pressure within the ductwork. This leads to lower overall energy consumption, especially in colder climates, where maintaining optimal indoor conditions is crucial. Studies show that adopting pre-insulated ducts can reduce energy consumption by up to 20%. However, in warmer regions, the effectiveness is slightly diminished due to solar heat gain. Lifecycle analyses support the environmental benefits by highlighting substantial long-term energy savings and reduced maintenance costs.

Quick Links

Products

Contact Us