E-mail:Machine@chinaventech.com Expert for pre insulated duct CNC cutting machine.

The Difference in Durability Between Pre-Insulated and Regular Ducts

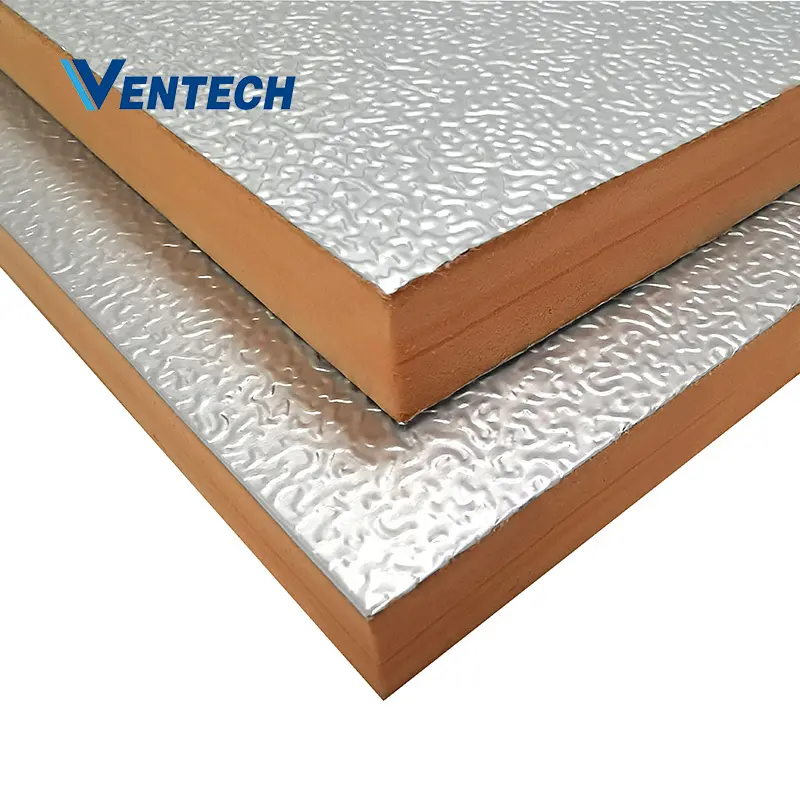

Pre-insulated ducts offer a distinctive advantage over standard ducts due to their factory-sealed design, which minimizes air leaks and enhances performance and cost-efficiency. This seal tightness not only improves energy efficiency but also significantly reduces maintenance needs and lowers energy consumption. While the initial installation cost may be higher, pre-insulated ducts often yield long-term benefits, including lower utility bills and a longer system lifespan. Furthermore, they perform exceptionally well in varying environmental conditions, ensuring consistent airflow even in extreme temperatures, which underscores their sustainability and efficiency.

Advantages and Disadvantages of Pre-Insulated Ducts

Pre-insulated ducts come with several benefits and some drawbacks:

- Improved energy efficiency - Enhanced insulation reduces heat loss and gain, leading to significant savings on utility bills.

- Consistent temperature control - Pre-insulated ducts maintain a uniform temperature, ensuring optimal performance of HVAC systems.

- Reduced air leakage - Sealed tightness minimizes drafts and contaminants, improving indoor air quality and system performance.

- Simplified installation - Factory-finished insulation and connections save time and reduce the risk of installation errors.

- Higher initial cost - The expense of pre-insulated ducts can be higher than traditional metal ducts, though long-term benefits often justify the cost.

Installation Methods for Pre-Insulated Ducts: Streamlining the Process

Streamlining the installation process for pre-insulated ducts is crucial for ensuring optimal performance. Proper alignment and securing the ducts prevent air leaks and maintain consistent temperatures. Standardizing procedures and using reinforced straps and clamps can significantly reduce gaps. Advances in materials such as polyisocyanurate insulation and snap-together systems further simplify the process. Regular inspections and the use of quality sealants at joints are essential for maintaining system efficiency and longevity. In cold climates, stainless steel straps and self-drilling screws enhance seal integrity, while in hot climates, polyisocyanurate insulation and robust maintenance schedules are key. Certain brands like CertainTeed and Owens Corning have demonstrated consistent performance in various climates, making them reliable choices for professionals aiming to streamline the installation process and ensure long-lasting performance.

Long-Term Durability and Efficiency of Pre-Insulated Ducts

The long-term durability and efficiency of pre-insulated ducts significantly enhance the performance of HVAC systems. These components offer superior insulation, reducing energy loss and enhancing overall system efficiency. They are particularly advantageous in high-humidity or corrosive environments, where traditional ducts may corrode over time. Additionally, pre-insulated ducts provide better moisture protection, extending their lifespan in humid climates. However, the initial cost can be higher, and proper installation is crucial for achieving optimal performance. Key aspects of installation include sealing joints and edges, securing insulation wraps, and using suitable tapes and grommets. Regular maintenance, such as periodic inspections and maintaining seal integrity, is essential to ensure system efficiency and longevity. In different building environments, materials and maintenance practices should be tailored to the specific needs. For instance, industrial settings require robust, corrosion-resistant materials, while commercial buildings can benefit from high-R-value, low-maintenance materials. Residential installations focus on energy-efficient, easy-to-maintain materials.

Rectifying Common Misconceptions

Misconceptions about pre-insulated ducts often undervalue their true benefits. Some believe that pre-insulated ducts are less durable and more expensive than regular ducts, leading to inadequate investment. However, pre-insulated ducts offer a seamless, moisture-proof insulation layer bonded directly to the duct walls, reducing thermal losses and noise, providing a more consistent and quieter environment. Moreover, recycled materials and reduced energy consumption contribute to a lower carbon footprint and better sustainability. While the higher initial cost is a factor, significant long-term savings from enhanced energy efficiency and lower maintenance needs make pre-insulated ducts a more economical choice.

Real-World Applications of Pre-Insulated Duct Systems

Case studies highlight the effectiveness of pre-insulated duct systems in diverse settings. In a high-temperature industrial facility, these ducts achieved a 20% reduction in energy consumption by maintaining stable temperatures and virtually eliminating air leakage. In a cold storage facility, consistent humidity levels were maintained, preventing condensation and enhancing food safety with reduced maintenance costs. A new commercial building saw a 25% increase in energy efficiency, compared to traditional uninsulated ducts. These examples demonstrate the durability and cost-effectiveness of pre-insulated ducts in various applications, making them valuable components in modern building design.

Installer Perspectives: Insights on Using Pre-Insulated Ducts

Installer perspectives emphasize the importance of careful handling and precise installation to maintain the integrity of pre-insulated ducts. Issues such as compression and damage during handling can compromise the insulation's effectiveness. Following manufacturer guidelines and employing trained professionals is essential to ensure the thermal performance and longevity of the ductwork. Additionally, pre-insulated ducts are highly valued for their enhanced temperature stability, contributing to more consistent indoor temperatures and improved HVAC system efficiency. While the initial cost can be higher, the long-term benefits, such as reduced energy consumption and lower maintenance costs, often justify the investment. Effective integration with smart HVAC systems further enhances the value of these ducts, as they can improve data accuracy and system performance. Overall, pre-insulated ducts offer significant advantages when installed correctly, making them a preferred choice for those seeking high-performance, energy-efficient HVAC solutions.

Quick Links

Products

Contact Us