E-mail:Machine@chinaventech.com Expert for pre insulated duct CNC cutting machine.

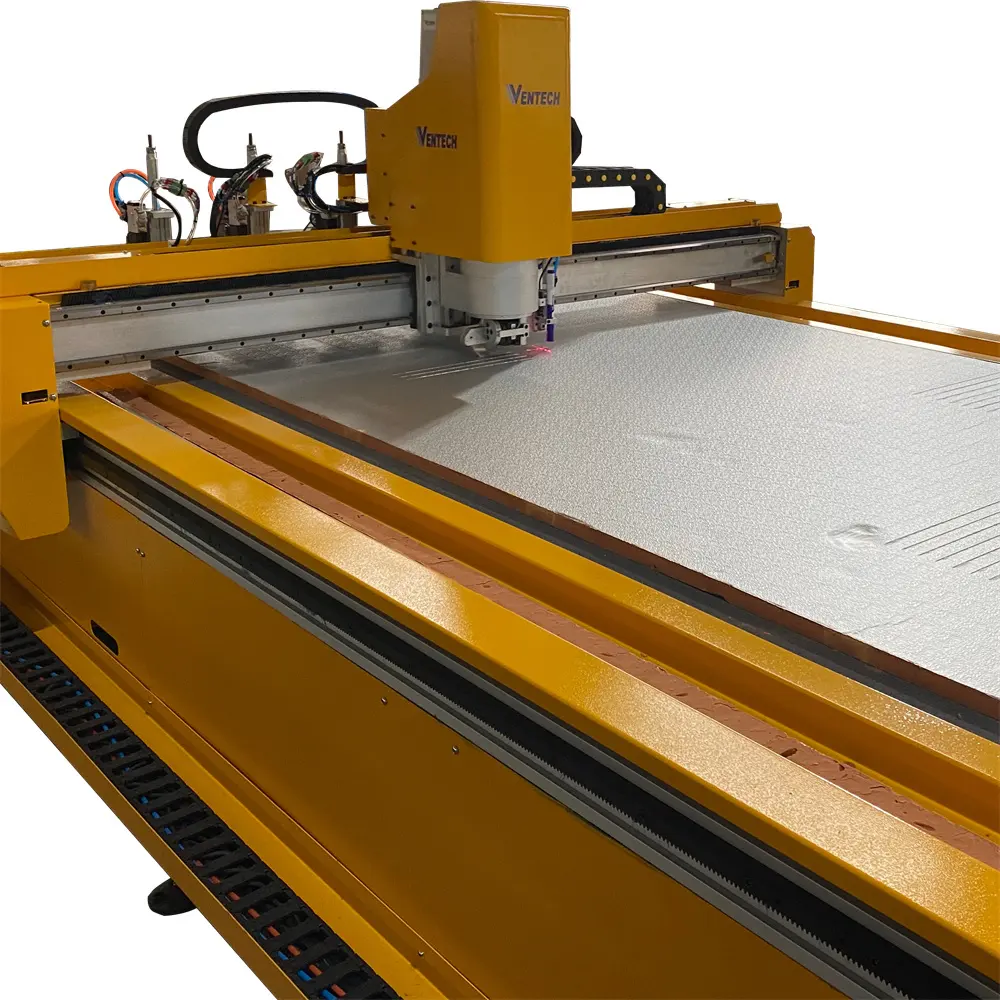

Pre-Insulated Duct CNC Machines Revolutionize Manufacturing

Advanced benefits and features of pre-insulated duct CNC machines include precision and automation, material efficiency, labor cost reduction, customization and flexibility, and real-time data and predictive maintenance.

Precision and AutomationCNC machines offer unparalleled precision, ensuring accurate cuts and fits, which significantly reduces the risk of errors and waste in manufacturing processes. This precision minimizes material waste and enhances overall product quality.

Material EfficiencyBy minimizing material waste and optimizing usage, CNC machines significantly lower costs and reduce their environmental impact. The precise cutting capabilities of these machines ensure that every piece of material is used efficiently, contributing to sustainability.

Labor Cost ReductionAutomation and enhanced precision reduce the labor demand and the likelihood of human error, thereby lowering overall labor costs and increasing productivity. This automation leads to more consistent and efficient production processes.

Customization and FlexibilityCNC machines can easily adapt to various designs and architectural forms, providing tailored solutions for complex projects. This flexibility allows for the creation of bespoke duct systems that meet specific project requirements.

Real-Time Data and Predictive MaintenanceIntegration with IoT sensors and AI algorithms enables real-time monitoring and predictive maintenance. This enhances system performance by ensuring that maintenance is performed before failures occur, thus reducing downtime and operational costs.

Cost Efficiencies and Energy Savings

Pre-insulated duct systems combined with CNC machines have brought significant cost efficiencies and energy savings to various industries. By enabling precise cutting and reducing material waste, CNC machines optimize the insulation performance of duct systems. Real-world success stories show that these systems can achieve up to a 30% reduction in HVAC system energy consumption. Enhanced air flow and reduced leakage contribute to lower operational costs and a positive environmental impact. Additionally, the integration of IoT and data analytics enhances system monitoring and predictive maintenance, further driving down energy usage and maintenance expenses. Sustainable materials, such as recycled and low-VOC insulating materials, are supported, leading to long-term cost savings and enhanced environmental performance.

Streamlining Manufacturing Processes

The integration of CNC machines for pre-insulated duct systems streamlines manufacturing processes, significantly improving precision, efficiency, and cost savings. These machines automate intricate cutting and shaping processes, ensuring consistent outcomes while reducing manual labor and minimizing material waste. Smart manufacturing technologies, such as real-time data synchronization and predictive maintenance, further enhance efficiency by enabling the detection of potential issues before failures occur, optimizing maintenance schedules, and reducing downtime. These advancements also contribute to more sustainable practices, fostering a culture of innovation and continuous improvement. Precise control over production processes not only speeds up manufacturing but also enhances the overall quality of the duct systems, leading to better installation outcomes and reduced maintenance costs.

Technological Advancements and Factory Automation

Technological advancements have transformed factory automation, bringing about improvements in precision, reduced downtime, and more efficient workflows. The integration of pre-insulated duct systems with CNC machines has enhanced overall manufacturing efficiency and necessitated the development of robust safety protocols and maintenance routines. To ensure worker safety, strict ergonomic guidelines, regular risk assessments, and the implementation of personal protective equipment and emergency response plans are crucial. Maintenance practices, including the use of condition monitoring systems and predictive maintenance programs, are key to preventing unexpected downtime and accidents. The adoption of AI and machine learning for predictive maintenance and process optimization has further enhanced operational efficiency, allowing for the anticipation of equipment failures and the optimization of production workflows. These technological advancements not only streamline manufacturing processes but also contribute to higher quality standards and environmental sustainability, making factory automation a critical aspect of modern manufacturing practices.

Case Studies and Examples of Successful Implementation

Case studies from various industries demonstrate the successful implementation of pre-insulated duct CNC machines. For example, Clearfield High School saw a significant improvement in production efficiency and accuracy by integrating these machines. In the construction and HVAC sectors, companies have reported a substantial increase in production speed and a reduction in errors. A company noted a 30% increase in production and a 20% decrease in mistakes. In the automotive industry, CNC machines enabled more efficient customization and faster prototyping, leading to a 50% reduction in duct fabrication time. These case studies highlight the importance of strategic planning, comprehensive training, and continuous support in ensuring a smooth transition. Key strategies include detailed process mapping, robust quality control systems, and technologies such as CAD software, MES, and IIoT for real-time monitoring. Workforce development programs that align with technological advancements are crucial, providing both technical and soft skills to students and employees. Effective communication and support for parents also contribute to the successful integration of advanced manufacturing technologies, ensuring a supportive and informed community.

FAQs Related to Pre-Insulated Duct CNC Machines

What are the advanced features of pre-insulated duct CNC machines?

Advanced features of pre-insulated duct CNC machines include precision and automation, material efficiency, labor cost reduction, customization and flexibility, and real-time data and predictive maintenance.How do pre-insulated duct CNC machines offer cost efficiencies?

By enabling precise cutting and reducing material waste, pre-insulated duct CNC machines optimize the insulation performance of duct systems, leading to up to a 30% reduction in HVAC system energy consumption.What benefits do pre-insulated duct CNC machines provide in manufacturing?

Pre-insulated duct CNC machines provide benefits such as precision, labor cost reduction, customization, real-time data, and improved energy efficiency, all of which contribute to better product quality and cost savings.How do pre-insulated duct CNC machines streamline manufacturing processes?

By automating intricate cutting and shaping processes, these machines ensure consistent outcomes, reduce manual labor, minimize material waste, and enhance overall efficiency.What are some real-world applications of pre-insulated duct CNC machines in manufacturing?

Pre-insulated duct CNC machines are used in industries such as construction, HVAC, automotive, and others to improve production efficiency, accuracy, and quality, leading to reduced errors and time, and cost savings.

Quick Links

Products

Contact Us