E-mail:Machine@chinaventech.com Expert for pre insulated duct CNC cutting machine.

How Duct Board Cutters Differ from HVAC Tools

A duct board cutter is a specialized tool designed for precise cutting of sheet metal and rigid duct board. Essential for HVAC system fabrication, these tools ensure clean, straight cuts to facilitate proper sealant application and prevent air leaks, thereby maintaining optimal airflow and system efficiency. Compared to general HVAC tools, duct board cutters offer greater control and accuracy, contributing to enhanced performance and longevity of HVAC systems.

Why a Duct Board Cutter is Not Included in Standard HVAC Tool Kits

The omission of duct board cutters from standard HVAC tool kits is often due to their specialized nature and the precision required for duct board cuts. While general tools like tin snips or scissors can suffice for many tasks, they are not suitable for achieving the clean, straight cuts needed for optimal system efficiency and ventilation quality. Duct board cutters provide consistent and precise cuts, critical for maintaining proper seals and airflow. Therefore, while the non-inclusion can lead to inefficiencies and increased labor costs, the long-term benefits in terms of improved precision, reduced maintenance, and enhanced system performance justify the inclusion of these specialized tools in standard HVAC tool kits.

Functions and Benefits of a Duct Board Cutter in Construction

A duct board cutter offers several key functions and benefits:

- Precision Cutting: Ensures tight, leak-free joints and precise connections, enhancing the overall efficiency and performance of HVAC systems.

- Versatility: Handles cutting, marking, and folding duct boards, reducing the need for additional tools and increasing work efficiency.

- Material Savings: Minimizes material waste through precise cuts, reducing costs and contributing to environmental sustainability.

- Quality Assurance: Provides consistent, high-quality cuts that ensure optimal fit and performance of ductwork, crucial for maintaining HVAC system integrity.

- Training and Skill Development: Facilitates proper training for operators, resulting in a well-trained workforce capable of performing precise cuts, leading to superior ductwork construction.

How to Choose a Duct Board Cutter

When selecting a duct board cutter, prioritize precision and ergonomic design:

- Adjustable Blades: Handle various material thicknesses while providing clean, straight cuts essential for proper sealing and insulation.

- Pivot Joints: Enable the tool to navigate tight spaces and follow complex curves, enhancing the fit of HVAC components.

- Ergonomic Handles: Reduce strain during prolonged use, enhancing safety and productivity.

- Safety Standards: Choose tools that meet safety standards and are backed by manufacturers with comprehensive training programs.

- Routine Maintenance: Clean and lubricate pivot joints regularly to ensure longevity and optimal performance, leading to reduced waste and cost savings.

Duct Board Cutter vs HVAC Tools: Comparative Analysis

Duct board cutters and HVAC tools serve distinct purposes within the HVAC industry:

- Duct Board Cutters: Valued for precision and ease of use, essential for creating smooth edges that enhance airflow and energy efficiency. They are user-friendly, especially for DIY enthusiasts, and require less maintenance, making them cost-effective.

- HVAC Tools: Offer a broader range of functionalities, including shear blades, crimping tools, and flange cutters, crucial for various tasks in HVAC installations. These tools are more powerful and capable of handling thicker materials, featuring safety features like blade guards to ensure a safer work environment. They require more intensive maintenance due to their multifunctional nature but are justified by their durability and longevity.

Different Types of Duct Board Cutters Available in the Market

Various types of duct board cutters are available, each designed to handle specific challenges:

- Manual Cutters (Tomahawk Style): Lightweight and portable, ideal for smaller, low-volume projects. Offer basic functionality with ergonomic handles for user comfort.

- Consumer-Level Power Cutters: Compact and affordable, provide decent precision for DIY and small commercial projects. Feature a laser-guided alignment system to minimize errors and waste.

- Professional Power Cutters: Equipped with advanced features like variable speed settings and adjustable blades, perfect for HVAC professionals. Offer exceptional accuracy and handle a wide range of materials.

- Digital Cutters: Integrate with CAD software and mobile apps, enabling real-time data syncing for precise cuts and streamlined designs.

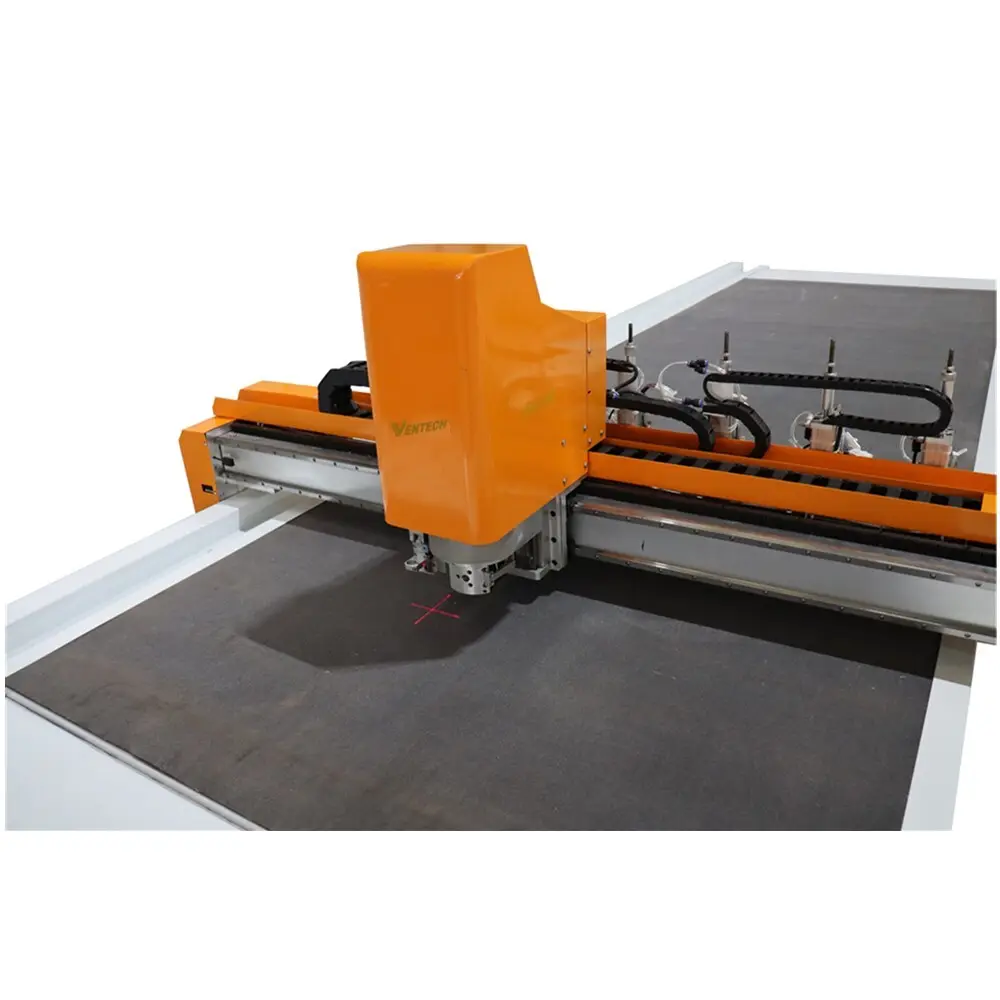

- High-End CNC Cutters: Produce highly precise cuts with minimal material waste, essential for large-scale industrial projects. Feature advanced technologies such as multi-axis control and automated feeding systems.

Potential Dangers of Using Non-Standard Tools to Cut Duct Boards in HVAC Installations

Using non-standard tools, such as reciprocating saws, for cutting duct boards in HVAC installations presents significant hazards:

- Jagged Edges: Produce sharp edges, leading to cuts and punctures, increasing the risk of chronic injuries and chronic safety issues.

- Air Leaks and Uneven Surfaces: Improper edge finishing can cause air leaks and uneven surfaces, diminishing system efficiency.

- Tool Failure: Prone to frequent failures in confined spaces, potentially causing electrical shorts or other malfunctions, endangering both job efficiency and environmental safety.

FAQs Related to Duct Board Cutters in HVAC Installations

What are the key benefits of using a duct board cutter in HVAC installations?

A duct board cutter offers precision cutting, ensuring tight, leak-free joints and enhanced HVAC system performance. It also handles various tasks like cutting, marking, and folding, reducing the need for additional tools and increasing work efficiency. Additionally, it minimizes material waste and provides consistent, high-quality cuts that ensure optimal fit and performance of ductwork.Why aren't duct board cutters included in standard HVAC tool kits, and what are the long-term benefits of using them?

Duct board cutters are often not included in standard HVAC tool kits because of their specialized nature and the precision required for duct board cuts. Because they offer consistent, precise cuts critical for maintaining proper seals and airflow, they significantly enhance system performance and longevity, justifying their inclusion despite initial costs.What specific tools are more commonly used in HVAC installation than duct board cutters?

HVAC tools commonly used in installations include shear blades, crimping tools, and flange cutters. These tools are more powerful, capable of handling thicker materials, and feature safety features like blade guards, making them essential for a range of HVAC tasks.What are the potential dangers of using non-standard tools to cut duct boards in HVAC installations?

Using non-standard tools like reciprocating saws can produce jagged edges, leading to cuts and punctures, and may cause air leaks and uneven surfaces. These issues affect system efficiency and increase the risk of chronic safety issues. Additionally, non-standard tools are prone to failure in confined spaces, posing a risk of electrical shorts or other malfunctions.How do you choose the best duct board cutter for your HVAC projects?

When choosing a duct board cutter, prioritize features such as adjustable blades for handling different material thicknesses, pivot joints for navigating tight spaces, ergonomic handles for reducing strain, and safety standards to ensure compliance. Regular maintenance is also crucial to ensure longevity and optimal performance, while training and support from the manufacturer help in mastering the tool's use.

Quick Links

Products

Contact Us